After years of figuring out what additive manufacturing—the new kid of industry—could and couldn’t do, 2016 seems to be when the technology finally started to settle in and become one of the gang. It’s gained worldwide acceptance and a feasible way to make many things, not just a few prototypes. The watershed moment may have been General Electrics acquisition of two European 3D printing companies for $1.4 billion.

GE Aviation says it will 3D-print more than 100,000 parts by 2020 to make lighter and more efficient engines, along with several other advantages.

What will happen in the sector in 2017? It will no doubt be a momentous year for manufacturers around the world, if even half of what President Donald Trump says he’ll accomplish comes to fruition when he starts the job on Jan. 20. From trade to new jobs, everything is up in the air.

We know you need to know what the 3D printing future holds, so we asked an expert in rapid prototyping, low volume manufacturing and how they tie into a global economy. His company is based out of Zhongshan, China, does about half of its business with the United States, and he himself from England. His name is Gordon Styles and he is founder and president of Star Prototype.

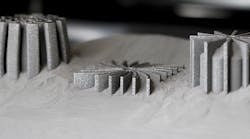

The engineer and entrepreneur began his latest venture in 2007, and operates out of a 55,000 sq. ft facility to provide plastic injection molding, and metal 3D printing. The latter is done by Direct Metal Laser Melting (DMLM), and creates rich, geometrically complex components with as little material as possible due to being additive, not subtractive.

We emailed him recently about the state of 3D printing in 2017 and here’s what he had to say.

NED: In your experience, what’s the overall state of additive manufacturing right now?

GS: 3D printing is very much on the rise. Unfortunately, many product designers are still working out how to design for metal 3D printing in a way that is efficient when it comes time to manufacturing. It is common for us to receive an inquiry for 3D printing and then suggest the use of different manufacturing processes better suited for the product design.

NED: What’s your big prediction for 3D printing in 2017?

GS: My biggest single prediction for 3D printing in 2017 is regarding the launch of the Hewlett Packard Jet Fusion 3D 4200. Since the late ‘80s and ‘90s, when SLS, LOM, FDM and many other technologies came out, there have been no real ‘step-changes’ in 3D printing technology. Well, in 2017 we will see the next step change in plastics 3D printing.

The HP Jet Fusion technology threatens to be five to ten times faster than anything else on the market, offers a very strong nylon, and every voxel will be individually colored. This will be the first time that product designers can genuinely consider a plastic-related 3D printing technology as a truly viable ‘low-volume manufacturing’ technology. HP even claims that many of the structural plastic parts in its own machines have been built using earlier versions of the HP Jet Fusion technology. The world has waited nearly two decades for a genuine step change in plastic 3D printing and now there will be one.

NED: What’s the more important additive manufacturing hurdle to overcome: print speed, post-processing, or materials available?

Metal 3D printing is where plastic was back in the early 1990s. One huge challenge that has been overcome in metals is the density and general quality of the metallurgy. We are experiencing accurate metallurgy upon testing and 99.8% density. This has allowed companies like GE and Airbus to confidently start producing small turbine blades and airframe components.

The problems facing metal 3D printing include support removal, warp, and speed. Support removal requires a revolution in the way that designers create parts for metal 3D printing. It is not like plastic 3D printing where you can tear off SL supports with your bare hands: try that with DMLM and you will have shredded fingers.

Support removal in DMLM requires some serious engineering. Supports can be minimized dramatically by designing the parts knowing that every element of the geometry must be self-supporting. For example, there can be no overhangs at less than 45 deg to the horizontal, which is perfectly possible. The problem is that if you minimize supports you can fall foul of the next trap, which is warping

But as mentioned before, overall the biggest challenge is finding applications that suit metal 3D printing, as most designers do not know how to design for metal 3D printing. The only reason the industry appears to be growing so fast is because metal 3D printing is not for prototyping: it is for production parts. The only prototyping that is being done is in preparation for a production run. The problem is that two-thirds of everything you build the first time fails with metal 3D printing. The good news is that once the part is optimized for the machine, then the reliability is extremely high and the main reason thereafter for failed builds is a failure in the machine.

NED: What’s your prediction for hybrid CNC/3D printing machines in the next year?

I think that hybrids will play an instrumental role in 3D printing in the future. I do not think it is a fad, more of a niche. If you make high-temperature aerospace shielding or high-temperature complex chemical vessels, then something like the Lasertec 65 Shape from DMG Mori is perfect for you.