Key to Success: Facet Precision Tool

Jeremy Bunting, Managing Director of Facet Precision Tool grew up in the cutting tool industry, getting a hands-on education from a young age and then using this experience to start his own business. From laying out a brand-new manufacturing center; to shaping and promoting Facet’s reputation; to training up a high performing team who are passionate about the craft of cutting tools—Jeremy has built the foundations for success.

Jeremy Begins

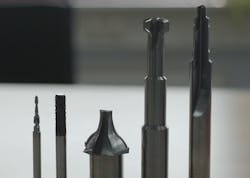

I started designing my first tools at age 14 in America as part of the family business, using manual grinding as well as conventional grinding to manufacture tools. After that, I moved on to the applications side—getting exposure to feeds and speeds and eventually moved to Europe. In Europe I worked for different tooling manufacturers, seeing different approaches to manufacturing and precision tooling. I started Facet Precision Tools in 2015 primarily to service the aerospace and automotive sectors. Both these markets require special tools with distinct needs. At Facet, we produce PCD, carbide cutting, and coated carbide tools through distributors and direct to customers. Based in Germany we sell locally as well as to France, England, and Spain. Through distributors, we service Africa, Sweden, Turkey, Hungary, Austria, Italy, and Mexico.

It's challenging starting a new business. We had a market and products in mind and we're in a unique position where we could decide if these are our target markets, what machinery and equipment do we need? I considered my past experiences in the industry and how can I apply any learnings to the future. When we entered the market, I wanted to have high-quality equipment, robust manufacturing processes, and be producing market-leading cutting tools. Since opening we have been growing steadily, in fact, last year we doubled our sales. As we expand we are looking at how we can attract more customers, consider if we need to add additional products, and as many people in the industry experience—are always looking for good people.

Establishing Grinding Capabilities

After deciding on a shop floor blueprint, we invested in a range of ANCA machines with two MX7 Linear’s, an FX7, and an EDGe as well as other equipment. We use the MX7s primarily for automotive tooling as they work well when grinding tools with larger diameters of 20, 25, and 32. We also run a lot of pocket grinding for PCD cutting tools on this model. The MX7 has a lot of horsepower that allows us to grind these tools in a very stable way. We use the FX for high volume carbide tooling. As an extremely rigid and thermally dynamic, stable machine I can rely on it to grind highly repeatable cutting tools. On the MX7 we have an ANCA spindle speeder that allows us to achieve higher rpm. We worked with ANCA to adjust the software to be able to provide a better stable pocket and more accurate pockets in our grinding process.

On the EDGe, we manufacture PCD tools. In the past couple of years, we have been developing PCD vein tools with our own blanks and cutting tool designs—working through and refining our processes. The EDGe has allowed us to have a high degree of accuracy when trying to grind a lot of the geometries. I found that as a process, erosion enabled the repeatability and the quality we were looking for. We also added a vision camera system on the EDGe, allowing for a quick inspection inside the machine, to get higher repeatability and better quality versus taking it out of the machine and putting it back in.

And then there is ANCA’s 3D Simulator program. Up to 95% of the designs and problem-solving are done on the simulator; testing the grinding process, reviewing, and modifying before you go into a machine. It is our strongest tool to increase efficiency and reduce waste and that is a major help to our profitability. For example, carbide is extremely expensive where you can be paying from 400 euros for a 32 mm standard rod.

The simulator also shows estimated grinding times which has been a great tool for us to reduce cycle times. Last time it took us, for example, 20 minutes to make this tool, but after considering a new idea or different approach we can reduce that time to 18, 17 or even 15 minutes all through experimenting in a simulated grinding environment. We have touch probes on all the machines that allow us to easily change wheel packs, qualify the wheel, and start moving quickly. It also allows us to remove human error and ensures higher finished quality. To be able to dress and probe the wheel, picking back up where you left off without having to change the setup is very advantageous. One of the main reasons we love ANCA machines is because of the software. We have found it to be extremely flexible and at Facet we don't use a lot of the standard ANCA programs and designs and instead do a lot of our work in profile editor, changing angles and profiles to meet the tool designs that we need. My Dad always said that ANCA was a software company that built a machine.

Facet Precision Tool comments on why building a team of craftspeople is key to success and whether the electric car is the demise of the cutting tools.

As we build our company we want to be known for quality. From the start, we have been trying to build our reputation for offering high-quality tools rather than just entering a market and throwing anything out there and seeing what sticks. We are methodical in our approach to manufacturing certain tools or entering a marketplace or approaching certain things. Even if this means we are a bit slower and more tactful. Just as important is our responsiveness to the customer through deliveries and application support. These are the foundations of our company. We start by listening—what does the customer want to achieve, am I understanding their needs correctly? Then I consider how the product could be improved, can we make other recommendations. We turn that request into a tool design that is checked by the customer. In aerospace, a common misunderstanding is a need for standard tools. Tools for aerospace require different lengths, diameters, and applications. There is also a high requirement for accuracy, in Europe for example, we find aerospace have applications that need to be measured to a couple of microns and use a variety of methodologies to make holes in different materials. It is a challenge to make a product meet quality standards while working across a range of material applications.

Building a Team of Craftspeople

I think working in specialty tools excites an element of craftsmanship. Every day is different, and you can take pride in your work, was it correct, was it to print? That is why we look for a person who is flexible, shows an ability to learn, grow, and absorb information. I train everybody in my plant as if they've never seen a grinding machine before. We invest time to build their knowledge base to understand the manufacturing and measuring equipment. Again, partially because we're into specials where every tool design is different, we don't have pre-written programs. I think one of the best characteristics of a toolmaker is an attention to detail. Often people can become over-invested in the productivity side—how many parts can I get through and how fast can I get them through the line. I train my team to be focused on the quality of the tool first and productivity second. And to meet these expectations of quality you have to have a high attention to detail. Just as important is to develop your team to have a passion for grinding. The more passion someone has for the product, the more likely they are to stay. Teaching your employee how to make a better-quality tool feeds their creativity and teaches them it is ok to have your own approach and style. At Facet, we have an open dialogue with our teams of why we do the things that we do.

Trends in the Market—Will the Electric Car be the Demise of Cutting Tools?

If I think about what I am seeing in the market I would say there is more competition in the automotive field than there is in the aerospace field, probably because aerospace requires more project work, more support, more testing, and more engagement with the customer. Automotive expects high-quality tools at very high tolerances—we have reamers that have tolerances of only a couple of microns.

Another focus of this industry is the price. As the use of composites in aerospace has increased so has the demand for PCD or diamond coated tools. For example, the Dreamliner or A350 or Boeing Dreamliner uses a large number of composites. These are extremely abrasive so if you use a carbide tool to grind composite materials, initially the tool works great but the wear curve is extremely high so after 150 holes, the amount of wear is accelerated on that tool until it becomes blunt. This changes the dynamic of the cutting, the heat, and burr creation, causing problems for the manufacturer. Whereas if you use a qualified diamond or PCD tool, you may be able to make it up to 1,500 holes. For a customer, that means higher productivity, fewer changeovers, less inventory, and a higher degree of quality for a longer period of time.

There is speculation that combustion motors will disappear and as motors disappear then the need for a lot of the cutting tools disappears. This is bringing up questions on how much electric cars will replace all other means of transportation. Personally I think there are a lot of hurdles that have to be overcome and we will see other opportunities as the market changes. I think as far as aluminum and composite manufacturing are concerned, we will see them trying to go lighter to make combustion engines more efficient. I think there will always be a need for niche and special products and that means more special cutting tools. That's one of the reasons why we were very comfortable moving into this industry. So as materials change—if it's more glass, carbon composites or aluminum—we're in a good position to move with the market and respond to those changes. I have established the foundations of Facet Precision Tools to be agile with design expertise, workforce skills, and manufacturing capabilities. We can and do adapt and invest in the machinery or develop our knowledge so we can meet the markets’ changing needs rather than focusing on materials.