Latest from Product News

What Are They Using? Equipment Choices From TerraPower, Hamilton Caster, Steel Mart, and More

Steel Mart Improves Its Cleaning Process With LISSMAC

Steel Mart, a steel processor, provides products and solutions to the construction machinery and waste-handling industries. Specializing in light and medium plate steel, Steel Mart processes raw flat plates into finished, direct-to-consumer products, including parts for construction machine attachments and trenching tools, ranging from 100 to 18,000 lb (45 to 8,200 kg).

As the company has expanded, it has faced challenges with its manual cleaning processes. With eight CNC tables producing parts, the cleaning process required 184 hours of machine time to be handled manually. The ratio of production time to cleaning time was approximately three hours of production to one hour of cleaning. However, the manual process couldn't keep up, creating backlogs and increased labor costs. The manual cleaning process, which involved chisels, hammers, and handheld de-slagging machines, was not only physically demanding but also one of the least sustainable job positions within the company.

While attending FABTECH, LISSMAC stood out to Steel Mart management and after a thorough assessment, LISSMAC recommended the SMB-M 1500-D2, a machine designed to streamline Steel Mart's cleaning processes.

Steel Mart's manual cleaning process previously took six hours to complete but they were able to get it down to 30 minutes with the LISSMAC machine while also getting cleaner parts. The ergonomic design of the machine also addressed concerns about worker health, reducing the risk of carpal tunnel syndrome and improving overall air quality by capturing slag in larger chunks and incorporating magnetic collection.

Steel Mart noted they realized six-figure savings annually in labor costs alone and increased productivity by 300%.

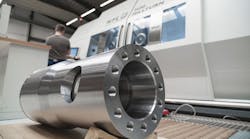

Valve Manufacturer Sees Success With WFL Millturn Technologies

HORA, a medium-sized family company based in Germany, focuses on developing, designing, and manufacturing control valves and actuators.

Since 2009, HORA has been concentrating on its production strategy for complete machining, which was limited by the size and weight of the components. In recent years, there has been an increase in the number of parts that could not be manufactured using complete machining methods. As a result, HORA needed a machine with enough chip space and better cutting performance.

To ease its challenges, the company decided to invest in a WFL MILLTURN 80 machine which handles milling, turning, and boring all in one. HORA also tends to opt for machines that work with a Siemens controller as it's "easier for the employees as it means that every machine is operated in a similar way."

"Machining at this scale is not new for us, but the cutting capacity is really remarkable and truly impressive! The cutting capacity was outstanding even during final acceptance of the machine, as the 160 indexable insert drill effortlessly cut the heat-resistant stainless steel (1.7335) with two tons of feed force and no vibration on the machine cover. In such moments, I like to grab the door but there were no vibrations to be felt," stresses Michael Beiwinkel, Head of Production and Building Technology.

The machine is currently working in two-shift operation. Four employees have undertaken the WFL training program in Linz and worked directly on the machine at HORA with the technician and now operate the WFL machine independently. Just eight weeks after the final acceptance of the machine, the M80 MILLTURN was sometimes working on single parts without a directly assigned operator. In the case of components with a longer machining time, the machine runs without supervision, especially overnight.

The machine is mainly used to manufacture valve bodies, perforated discs, perforated cages, and plugs.

Konecranes Supplying Equipment for TerraPower's Natrium Reactor Demonstration Plant

Konecranes will supply a fully customized 125-ton hoist crane, including a 15-ton auxiliary hoist and a top-running overhead crane with dual trolleys, to TerraPower's Natrium Reactor Demonstration Plant (a TerraPower and GE-Hitachi technology project) in Wyoming. The order was placed in June 2024 from TerraPower's engineering, procurement, and construction partner Bechtel. Installation is planned for the fall of 2025.

Founded by Bill Gates, TerraPower is developing advanced nuclear technologies to provide safe, sustainable, and cost-effective energy solutions.

The crane will be used at the Wyoming site’s Test and Fill Facility (TFF) for maintenance and production support. The TFF is a non-nuclear facility that stores ~400,000 gallons of sodium needed for Natrium's coolant system.

The crane's dual trolley design allows for synchronized operation of trolleys and hoists for precision and efficiency. The crane's features, including a main hoist with an 86-ft (26 m) reach and an auxiliary hoist with a 136-ft (40 m) reach, all within tight envelope tolerances.

Hamilton Caster Installs New Laser Cutter From AMADA

The AMADA AMNC 4ie laser cutter is expected to deliver more for Hamilton's customers.

ENSIS 3015 RIe w/Rotary Index Features:

- ENSIS technology automatically adjusts the laser beam's properties to process a wide range of thin-to-thick material without a lens change

- AMNC 4i control

- ENSIS technology allows for continuous variable beam control across every thickness of material with no setup

- 1.4g acceleration over the entire work area

- Water Assisted Cutting System uses an adjustable water mist to absorb heat generated by the cutting process

- Cut Process Monitoring for automatic pierce detection as well as plasma detection for thick stainless steel and aluminum

- SFP (Spatter Free Pierce) function for cleaner high-speed piercing in thicker material

- Interlocked enclosure surrounds cutting area to ensure safety

With an ongoing commitment to vertical integration by moving production in-house to reduce reliance on third parties, provide shorter lead times, and streamline product design, Hamilton Caster's choice for a new laser cutter will help it to product custom designs and heavy-duty parts faster, with the same precision of course.

This purchase comes a year after Hamilton chose to implement two new vertical lathes—the Puma V Series from Ellison Technologies—that lessened lead times, specifically for its large, heavy-duty wheels.

With the new laser cutter that can cut up to 1-in (25 mm) steel, Hamilton has stated that "this laser delivers consistent, high-quality results every time. No errors. No do-overs". The company has also noted that with its increase in in-house production, there has been a reduction in WIP (work in progress) inventory which will create lower costs that will be passed on to the customers.