Petrochemical Plant Gets an Upgrade With Unique Steam Atomization Design

Ethylene units in refineries and petrochemical plants require reliable and durable steam control valves to regulate steam temperatures for process control. At a leading Chinese engineering company’s ethylene unit, to modernize the plant, operators replaced failing valves with steam converting valves that feature a unique steam atomization design. The new steam converting valves with an integrated cooling system were delivered in record time. It offered the company the highest rangeability and superior thermal shock risk reduction for the downstream piping system, with no requirement for a downstream liner.

Pressure Reduction and Desuperheating Valves at Power Plants

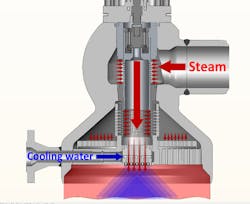

The steam converting valve (SCV), also known as a pressure reduction and desuperheating (PRDS) valve, combines pressure reduction for steam pressure and water injection for temperature reduction.

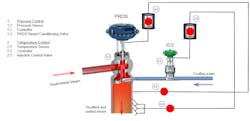

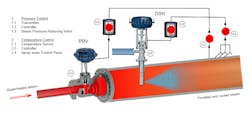

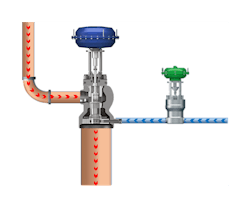

PRDS valves at power plants are normally located downstream of the boiler, parallel to the high pressure, intermediate pressure, or low-pressure turbine stages, to bypass the turbine and convert the steam from higher pressure and higher temperature to lower levels (photos 1 and 2). If the plant is a cogeneration plant, there is also an additional steam extraction stage, in which case the PRDS is installed downstream of the boiler for the process of steam creation (photo 3).

The PRDS uses cage-guided multistage trims and perforated plates for pressure reduction and also integrates cooling technologies, like steam assist. When the cooling function is not integrated with the trim construction but is a downstream application at the outlet, it's usually called a steam pressure reduction valve (PRV) with additional downstream cooling (DSH).

Figure 1 shows the components of a PRDS with an integrated cooling system, while figure 2 shows the installation of PRV with additional downstream pressure injection for cooling.

Plastics and Resin Manufacturing Firm Required Replacement Steam Converting Valves

The leading Chinese engineering company, based in Puyang, China, specializes in plastics material and resin manufacturing. The company needed to purchase new steam converting valves to replace a different vendor’s failing 10-year-old valves that were showing serious signs of wear.

Operators were concerned the failing valves could lead to loss of process control; cavitation can result if the steam temperatures are not achieved. Operators found that when the valves were open—even a small percentage—the entire flowrate was traveling through.

The company invited the original supplier and several others to participate in a closed bid to evaluate a range of valve choices on the market.

Valve selection can be difficult since there are limited options for the large (10-inch) control valves that are used for cooling steam from the high temperatures of the boiler to the process temperatures needed for ethylene in petrochemical plants. The company also had a very tight delivery requirement of 24 weeks, which is less than half of the typical 50 to 60 weeks usually required.

Several vendors offered steam converting valves with a steam atomizing design, while one vendor proposed steam converting valves with ring-type spray nozzles.

The company selected PRDS valves made by CIRCOR/Schroedahl. Only Schroedahl could meet the tight delivery time and offer the technical solution needed to solve the company’s requirements.

With a manufacturing site in Germany and a commercial office in China, Schroedahl’s proximity to the petrochemical plant helped it understand the customer needs.

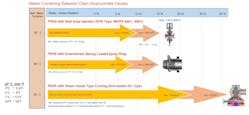

Figure 3 shows a comparison of the PRDS valves received during the bidding process. The Schroedahl valve has the highest steam rangeability (50:1), with a maximum of 45% water and temperature accuracy of +/- 5°F.

The Schroedahl solution also offered a unique steam assist system that uses high-pressure steam with high kinetic energy to crack the injection water into extremely small droplets—similar to a fine fog.

The system enables the plant to operate at extremely low load conditions and handle difficult start-up conditions. It also offered thermal shock risk reduction for the downstream piping system with no requirement for a downstream liner.

Other options would have required an additional cooling device—which would have resulted in more cost to the customer.

Figure 4 shows the PRDS with an integrated steam assist cooling system, along with a photo of the plant/ethylene unit. Figure 5 is a graphic that shows the valve’s operation, which is ideal for evaporation cooldown near saturated temperature (3°C oversaturation) and for preventing thermal shock.

The PRDS selection guide shown in Figure 5 provides additional information on the available options, displaying that the option selected was the best solution for high downturn duties.

The Steam Assist Advantage:

The Steam Assist system uses high-pressure steam (high kinetic energy) to crack the water into extremely small droplets (like fog)—no other system can create such a perfect cooling/evaporation. (See Figure 6.)

The result is the highest rangeability; the system can operate at extremely low load conditions, handle difficult start-up conditions, and provide perfect thermal shock risk reduction for the downstream piping system, with no downstream liner needed.

Focusing On Customer Needs and Production Helps Meeting Delivery Requirements

High-level precision engineering is required to develop a valve that controls the process and achieves good performance for applications of this temperature and sizing. Developing such a valve typically requires long delivery times, often 50 weeks or more. Achieving the 24-week goal was accomplished using a novel new approach that focuses on the customer, rather than the product.

Whereas in the past an engineering team was tasked with developing a specific valve product, the new approach uses an engineering specialist with a focus on the application-specific customer solution. Engineering teams are working on one product only—and the same team works with a manufacturing expert to assemble this particular product for this particular customer. In effect, the approach combines engineering to order with assembly to order.

Achieving the required 24-week delivery time was extremely ambitious for custom valves. The normal delivery time for one DU valve is approximately 28 weeks; projects requiring several valves usually take between 32 and 40 weeks.

New Strategy Pays off for Petrochemical Plants and Refineries

The new PRDS valve development strategy is based on a philosophy that PRDS valve needs are highly specialized, and products cannot be developed for standard use. Instead of working on several standard product projects, there is a focus on developing products that meet customer needs and dramatically decrease delivery times.

In addition to the ethylene unit, the CIRCOR/Schroedahl PRDS valve has been used at various petrochemical plants in China, as well as paper factories, chemical plants, and wherever steam is produced for production.

With their high rangeability and shock risk reduction for the downstream piping system, they provide customers with the perfect cooling and evaporation system.