Metal cutting leader, Sandvik Coromant, has developed a new 3D modeling technique that can 3D print up to 200 plastic face shields in the time traditional methods require to print one. Using stacked model data, the technique can dramatically increase 3D printing output, assisting in producing face shields for healthcare workers fighting COVID-19. Having publicized this data for free, Sandvik Coromant encourages other businesses to use this method to assist in face shield production.

Sandvik Coromant’s industrial facilities in Sweden are usually reserved for manufacturing metal powders into intricately engineered components. Today, the organization’s metalworking expertise and 3D printing capacity is being redeployed to produce personal protective equipment (PPE) for healthcare workers with some of the organization’s plastic 3D printers.

Several businesses are already producing 3D printed face shields. However, because 3D printers are usually restricted to printing one CAD file at a time, production output has been slow. To solve this problem, engineers at Sandvik Coromant’s Press Tools department have developed new modeling progress to allow machines to recognize a stack of multiple face shields as one solid CAD file.

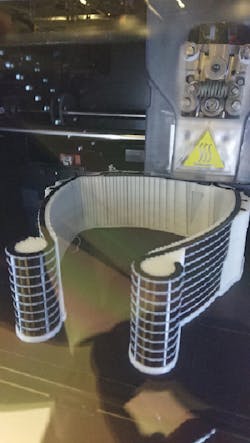

Duplicating the 3D image data of a single face shield, engineers at Sandvik Coromant are able to stack multiple shields on top of each other. Using a dual extruder, the 3D printer can then be instructed to create structural support between each product—essentially printing a thin string of plastic between each shield. Printing this support in water-soluble material allows the shields to be easily separated once printed.

Sandvik Coromant’s Press Tools division is now able to manufacture 42 plastic face shields per 3D printer during each production batch—a process that previously took 48 hours to manufacture just one face shield. Larger 3D printers could use this same technique to print up to 200 face shields in a single production batch.

Sandvik Coromant hopes that this technique will be adopted by other businesses with access to a 3D printer as the most efficient method for producing face shields. In fact, the company has already shared 3D model data required with Protech, the leading Nordic supplier of 3D printers from Stratasys. A distributor of 3D printers for the hobbyist market has also shared the data with its network.

“Printing several parts at a time is the optimal method for producing a high volume of face shields when using a 3D printer,” explained Christian Dingfors, Production Engineer at Sandvik Coromant Press Tools. “In the ongoing effort to support healthcare workers against COVID-19, we need to contribute to the production of personal protective equipment (PPE) as effectively as possible. That is why Sandvik Coromant wants to share this technique and the necessary imaging data with as many businesses as possible. We want every facility with 3D printing capacity to get involved.

“We encourage any business that has access to a 3D printer to contact us for guidance on how to deploy this printing technique. We are happy to share the 3D imaging data with anyone, including small businesses and hobbyists, that want to contribute to this essential cause,” concluded Dingfors.

Having obtained more than 3,000 overhead projector films, several divisions in Sandvik Coromant are now using their 3D printing capacity to produce face shields. For instance, Sandvik Coromant’s Press Tools Division has halted all non-critical production runs for the 3D printers it has on-site, with 75% of printing capacity now dedicated to producing face shields.

The shields will be donated to hospitals in the Sandviken-Gävle, Gävleborg, and Stockholm regions of Sweden, but Sandvik Coromant anticipates the initiative will be replicated globally—not just within Sandvik, but among the larger business community.

Elsewhere, in the US, when Wally Calayag, a Sandvik Coromant Sales Territory Engineer in California, saw the pain that surgical masks were causing medical professionals at a nearby hospital where his wife works as a nurse, he had an idea. Armed with a 3D printer and open source files, he started printing surgical mask extension straps, otherwise known as ear savers straps. And it wasn't long before he was making deliveries of these straps to the hospital to help those on the front lines, and in doing so, encouraging others to join the cause.

“Sandvik would never compromise when it comes to keeping employees safe,” explained André Larsson, R&D Technician at Sandvik Coromant’s Additive Manufacturing Division. “Right now, we can help protect medical personnel by keeping them safe and able to help those infected with COVID-19. Our lives depend on these medical professionals — and we cannot let their safety be compromised while they are saving lives.”

More information on Sandvik Coromant’s efforts to support the battle against COVID-19 can be found on the Sandvik Coromant website at www.sandvik.coromant.com. For guidance on deploying the 3D modeling technique, please contact Christian Dingfors, Production Engineer at Sandvik Coromant on [email protected].