ProMat 2025: Breakthrough AS/RS Cube Provides True Modularity

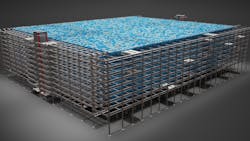

Freespace Robotics' high-density, dynamic storage cube uses autonomous robotics to deliver a high-turn, small-footprint, high-rise automated storage & retrieval system (AS/RS) that can incorporate conveyor functions—sortation, sequencing, pre-staging, each picking, and order buffering—for a wide range of industries, products, and materials under the control of a warehouse execution system (WES) that combines inbound and outbound material flows together.

The system's "Carrier" robots clear a 20-tray deep lane in 40 s and simultaneously put away and retrieve product in just one trip. It can also handle standard and large trays, full cases, and individual "each" picks, with trays capable of supporting loads up to 100 lb. Stackable trays can be stored in the cube, reducing floor space and allowing immediate replenishment access.

Freespace Robotics AS/RS solution will be revealed at ProMat's Startup Pavilion #E11200SP

Visitors will be able to meet the founders and learn how the system was designed from the ground up.

Freespace Robotics will also host a seminar in the Startup Theater to highlight the design, capability, and versatility of its solutions.

The system's modular rack design expands vertically and horizontally as needed, making it adaptable to greenfield and brownfield sites. Its ability to operate on uneven floors, navigate unconventional layouts, and operate with different ceiling heights makes it extremely adaptable to the demands of any facility. Additionally, its electro-mechanical components are positioned outside the racking structure for easy maintenance.

The power rail systems eliminate reliance on batteries, lowering costs, system downtime, fire risks, and insurance premiums. With lifts of up to 70 ft for high-rise and high-bay designs, the modular structure easily handles unknown demands, changing product, and changing capacity needs without reconstruction, or major retrofitting.

A plus is that the system relies on domestically sourced parts to enhance reliability and resilience.

Click play on the videos below to see the system in action.

Some applications the system can handle are:

- Shipping Buffers: Transforming dock operations with efficient order buffering, sorting, and sequencing within the cube for right-time delivery to dock.

- Cross Docking Operations: Reducing labor needs and operational footprints for time-sensitive processes.

- Goods-to-Person (GTP) Systems: Delivering high-speed, accurate order fulfillment.

- Integrated WES Option: Manages the broad range of popular warehouse management system (WMS) offerings as well as Legacy WMS systems.

- Last-Mile Delivery Optimization: Performance breakthroughs for challenging multistop delivery operations where weather, traffic, and congestion can impact route orders and performance. Meaningful reductions in shift time, delivery costs, and material handling.

Features:

- Robots move, store, or retrieve more than one tote at a time

- Robots and components are outside the structure

- Additional robots do not create additional congestion

- Items can be stored and retrieved in a single trip

- Cube is accessible from more than one side

- Good move without lifting or fighting gravity

- Spills or jams create minimal, if any, disruption or stoppage

- Simple parts, simple movement, simple power, simple repair

- No dependency on battery power

Freespace Robotics

Pittsburgh, PA

Pilot/Sales/Operations: [email protected], [email protected]

freespacerobotics.com