Next-Generation Workholding System

Nov. 23, 2020

Related To:

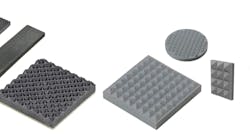

A new line of 52/96 workholding technology for CNC machining operations—available in January 2021—consists of vises, bases, and mounting systems that maximize holding power in a compact, quick-change modular design that reduces setup time and process variability. It is designed for 3, 4, and 5-axis machining centers.

Mate’s workholding line offers a selection of options:

- Mate DynoGrip self-centering vises feature maximum holding power in a compact system with minimal part movement and zero-point quality engagement with a four-post pull stud pattern.

- Mate DynoLock quick change bases provide zero-point quality engagement with a four-post stud pattern and best-in-class center accuracy and repeatability.

- Mate DynoMount system includes tombstones, pyramids, risers, and dual right-angle mounts that feature zero-point quality engagement for four-point stud patterns.

The Mate 52/96 workholding system includes QuickSpecs, Mate’s unique product identification system. QuickSpecs allows real-time access to critical user data, CAD models, and potential integration into business systems. Additionally, the product supports common robotic interfaces and palletizing systems to support factory automation.