Hilma.UC 125 Universal Machine Vise

The Hilma.UC 125 machine vise streamlines setup for different workpieces while reducing the need for multiple clamping devices across a wide range of clamping tasks.

The "UC" in the clamping system's name stands for Universal Clamp, as this vise can be easily adapted to accommodate a wide variety of workpiece geometries in just a few simple steps. The Hilma.UC 125 achieves flexibility through its separable base and two parallel slides, which are positioned using an adjustment spindle. Workpieces are securely clamped with a tension spindle, generating a tensile force of 52 kN, all while a center bearing ensures precise and centered alignment with repetitive accuracy.

By rotating the tension spindle, force is precisely applied to the workpiece via the outer clamping claws on the clamping jaws positioned above the workpiece stop. This flow of force prevents any stress on the base, effectively eliminating the possibility of clamp bending and ensuring the workpiece remains firmly in place.

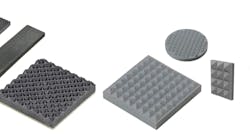

The jaw opening can be extended up to 24 in. (600 mm). Additionally, a variety of clamping jaws tailored for raw and finished parts, cubic and round workpieces, are available within the modular system. Designed to be easily accessible from all angles, the vise enables 5-axis machining within a single setup. However, its versatility extends beyond 5-axis machining, making it compatible with 3 and 4-axis operations as well.

With its universal modular design, the HILMA.UC 125 offers not only extensions for different clamping widths but also numerous mounting options adaptable to specific applications. The clamp can be directly placed on the machine table or integrated into a zero-point clamping system. Furthermore, flexible adapter plates simplify the realization of various clamping tasks, making it an indispensable asset for accommodating workpieces of diverse sizes and geometries.

- For 3, 4 or 5-axis machining centers as well as turning and milling machines

- Center clamping with pull-down effect

- Modular with versatile accessories

- Clamps small workpieces up to large plates

- Adaptable to different workpiece geometries in just a few steps

- High degree of freedom and optimum accessibility to the workpiece

- High clamping force

- Fast feed rate

- Always holds small and large workpieces in zero position (± 0.01mm)

- No force applied in the base

- More accurate and faster production

- Less tool wear

- Cubic and round workpieces

- Combination with STARK zero point clamping system as standard (retractable nipple bore holes)