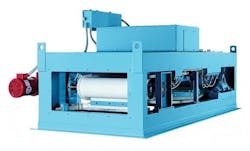

Model 260 Weigh Belt Weighers/Feeder for Closed-Loop Operations

The heavy-duty Model 260 Weigh Belt Weighers/Feeders accurately weigh and/or totalize the flow of dry materials in a wild-flow configuration, or meter dry solid materials in a controlled, closed-loop configuration as a weigh feeder.

The Model 260(WF), operating as a weigher and/or totalizer, continuously weighs material passing across the belt while producing an output signal directly proportional to the weight of product flow. Belt speed is constant and the rate of flow is not controlled, only weighed, by the weigher’s multiprocessor controller. The controller, which continuously monitors and totalizes the flow of material, displays the rate at which product is flowing, and produces a precise proportional-to-weight output signal that can be used for various process functions. The Model 260(WF) Weigher is also capable of batching to a preset total.

When operating as a weigh feeder, the Model 260(F) continuously controls the feed rate (or rate of product discharge off the belt) in relation to a feed rate setpoint via modulation of the belt speed by a multiprocessor-based control system. The belt, driven by a variable speed motor, is continuously regulated to precisely maintain the selected feed rate.

All Model 260 Series Weighers/Feeders feature Acrison’s high-resolution, non-load cell based, counterbalanced weighing system mounted above the weigh belt, out of the product metering zone.