Bridge Replacement Allows for Larger Cargo Ships

The Gerald Desmond Bridge Replacement Project in Long Beach, California, once built, will be the second-tallest cable-stayed bridge in the U.S. with the highest vertical clearance of any cable-stayed bridge in the country. Positioning the pier decks called for patience and precision; crane and heavy lift rigging specialist Bigge Crane and Rigging Co. used Enerpac’s strand jack technology to lift the decks into position over a 10-hour period.

Built in the late 1960s, the Gerald Desmond Bridge is in urgent need of replacement. It stretches over the entrance to the Inner Harbor of the Port of Long Beach, the second-busiest container port in the U.S., after the neighboring Port of Los Angeles, and generates approximately $100 billion in trade. When the bridge was constructed, cargo ships were one-sixth the size they are today. Although the Port of Long Beach’s Outer Harbor docks are “big ship ready” and already handling the world’s largest cargo vessels, the existing bridge prevents these cargo ships from reaching the Inner Harbor.

Started in 2013, The Gerald Desmond Bridge Replacement Project is a “design-build” project, combining project design and construction into one contract rather than the conventional three-stage: design, bid, build. By being more efficient, design-build projects have the potential to be built faster, and at a lower cost, than traditional construction projects. The Bridge Replacement Project is a joint effort of Caltrans and the Port of Long Beach, with funding contributions from the U.S. Department of Transportation and the Los Angeles County Metropolitan Transportation Authority (Metro). Construction of the bridge is managed by SFI JV, a joint venture organization comprising Shimmick Construction Inc., Spanish company FCC Construction, and Italian company Impregilo S.p.A.

Photo courtesy of the Port of Long Beach

When completed in 2019, the Gerald Desmond Bridge Replacement Project will span the Port of Long Beach’s Back Channel with a deck rising 205 ft above the water; high enough to accommodate the newest generation of container ships. With three lanes in each direction plus safety lanes, it will be wider and better able to serve the current 68,000 vehicle trips that travel over the current bridge each day. It will also include a dedicated bicycle path and pedestrian walkway.

The Gerald Desmond Bridge Replacement will be built with a cable-stayed design based on two 515 ft steel-reinforced concrete towers, that transition from an octagonal base to a diamond shape at the top. Forty steel wire cables will be used to connect each tower to the bridge deck in a fan-like pattern. The longest cable will be 573 ft. The main span and back spans will be 2,000 ft long and 205 ft above the water. The total length of the bridge from west to east will be 8,800 ft, including 2,000 ft for the cable-stayed span, with a 1,000 ft main span flanked by two 500 ft back spans. One-hundred columns will support the west and east approach spans: 3,117 ft and 3,035 ft respectively.

Bigge Crane and Rigging’s task was to lift the 1.35-million-pound pier tables for each of the two towers, which will form the east and west ends of the 2,000-foot main span extending over the water channel. In preparation for the positioning on the pier tables, four-column falsework was installed on each of the two towers.

Photo courtesy of the Port of Long Beach

Bigge used Enerpac stand jacks to lift the pier tables. “The strand jack is perfect for this kind of job,” said John Levintini, Projects Operations Manager at Bigge Crane and Rigging. “It would have been impractical to use a crane given the size and weight of the pier table. The strand jack is the best choice in terms of both lifting capacity and cost.”

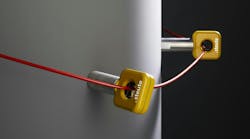

Enerpac strand jacks were positioned at each corner of the falsework. The strand jack lifting technique originates from the concrete post tensioning principle. A strand jack can be considered as a linear winch. In the strand jack, a bundle of steel cables or strands are guided through a hydraulic cylinder; above and below the cylinder are anchor systems with wedges that grip the strand bundle. By stroking the cylinder in and out while the grips are engaged in the anchors, a lifting or lowering movement is achieved. Enerpac has refined the strand jack technique making it easier to deploy and manage with automated locking – unlocking operation, as well as enabling precision and synchronous lifting and lowering by a single operator. Telescopic strand guide pipes, and ‘palm trees’ prevent bird caging and allow easier cable management. Heavy-lifts of thousands of tons is possible using strand jacks.

Mike Beres, Sales Director Americas, Enerpac Heavy Lifting Technology, noted, “Strand jacks pack tremendous lifting capacity into a small footprint. Moreover, the system software can control up to 60 jack/pump combinations, so the potential for large-scale synchronous lifting is quite scalable. The flexibility of the strand jack system allows Bigge to use this equipment on many other projects across multiple industries.”

Photo courtesy of the Port of Long Beach

Enerpac HSL 50006 strand jacks, each with 48 steel strands, were used to lift the steel framework pier table positioned around the base of the tower onto the four-column falsework. Synchronized control of the strand jack allows all four jacks to lift simultaneously, ensuring the structure remains balanced and does not tip. Each incremental lift was 18 inches, with the entire lift of the pier table taking 10 hours.

Bigge synchronized the lift through a strand jack computer. “The lift was straightforward. However, maneuvering the pier table into its final resting position on the falsework was a delicate operation — the final alignment was coordinated with the strand jack and visual feedback by engineers on the piers,” John Levintini noted.

Installation of the pier tables took place during April and May this year. First, one pier table was installed, then the four strand jacks deployed to the falsework on the other tower for the second pier table lift.

With the east and west towers’ pier tables in position, the first cable strands have now been installed. Each pier table is suspended by four cable strands running from the corners up to the first casing hole in the tower. Following the removal of the falsework, cranes will be lifted onto both pier tables to begin the balanced-cantilever construction of the main span. Bridge segments will be added symmetrically on both sides of each pier table, extending toward each one’s respective end bent (where the main span meets the approaches) and the center of the bridge over the water. The bridge is expected to be completed by the end of 2019.