Strand Jacks Used for Precise Lift at Nuclear Station

Duke Energy owns and operates regulated and non-regulated power plants throughout North America. The company has a diverse mix of generation resources including nuclear, coal-fired, oil- and natural gas-fired, as well as hydroelectric power plants.

One of the Duke-owned power plants is the Oconee Nuclear Station located in Seneca, South Carolina. Since beginning its operation, this nuclear station has safely generated more than 500 million megawatt-hours of electricity, being the first nuclear station in the United States to achieve this milestone. Oconee is one of the nation’s largest nuclear plants with a generating capacity of approximately 2.6 million kilowatts. This is enough electricity to power 1.9 million homes.

Engineered Rigging, well-known for custom solutions in the nuclear industry, was tasked to replace two feed-water heaters at the Oconee plant. The overall challenges of this job were the tight clearances, equipment obstacles and asbestos insulations. The existing overhead crane did not meet the rigging requirements for extracting the old units vertically. The heaters weighed 126,000 pounds and were 40 ft long, along with mechanical piping and nozzles attached that could cause interferences while lifting out. The customer was seeking a single failure-proof system that mitigated risk and was cost-effective.

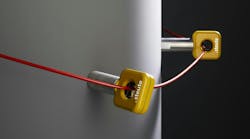

The Engineered Rigging team came up with an innovative solution to meet the needs and expectations of their customer. The team developed a temporary lifting device (TLD) using Enerpac strand jacks and customized trolleys that were installed on top of an existing bridge crane.

The TLD was developed with the goal of capacity and ability to lift over a long distance while utilizing computerized controls. The TLD was designed to work in x, y and z axes in precise distances to allow control of the lift. The strand jacks were the lifting or hoisting device on the TLD in the z direction and the strand jack pump auxiliary ports were used to control ancillary trolleys and shift cylinders in the x and y direction. The control system allowed for remote control of the whole evolution from a safe nearby location.

The two strand jacks located on the TLD were selected because of their capacity; having two pieces of 200-ton strand jacks met the single-failure-proof system requirement from the utility company’s specification for rigging and handling over safety-related equipment. The strand jacks also had the smoothest transition while lifting the equipment out of its resting place.

“In order to make this process go smoothly, we had to choreograph a removal process,” said Christopher Cox, President at Engineered Rigging. “Every time the vessel moved as it was pulled out of the hole, we had to rotate or side shift to miss obstructions. The clearance was only 5/8 of an inch on one side.”

Enerpac’s HSL20006 Hydraulic Strand Jacks provide precise synchronous control with heavy lifting capacity in an economical, compact and reliable footprint. They are powered by electric or diesel-driven hydraulic power packs and controlled by their Smart Cylinder Control System (SCC) to ensure full control of lifting and lowering operations.

“We were able to complete the job ahead of schedule,”said Cox. “Our engineers not only develop solutions, but they also work with them in the field. This allows us to really be able to think outside the box and push the limits for our clients.”

“The Enerpac and Engineered Rigging teams work well together,” said Mike Beres, Sales Director at Enerpac.“They know the applications and we know the equipment. Together we can come up with new solutions for clients that were never thought of before.”