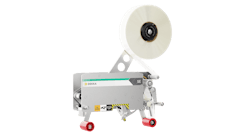

SELECT Synchro Selective Soldering System

The SELECT Synchro selective soldering system is for high-volume printed circuit board assembly applications. It is a multi-station selective soldering system that uses a unique, synchronous motion to increase throughput, improve cost-of-ownership, and provide flexibility for electronics manufacturers.

The system can replace existing selective soldering operations to improve yield and save space for many through-hole and SMT mixed-technology soldering applications. Furthermore, the Synchro system can help electronics manufacturers to step away from wave soldering with its faster, flexible, and efficient operations.

Inside the system, a board is pulled at a constant speed through the fluxing, pre-heating, and soldering process steps. The flux and solder applicators are programmed to follow and treat boards as they travel through the equipment to deliver synchronous-motion selective soldering. Multiple solder pots and different nozzle sizes are available to provide flexibility with solder quantities, solder alloys, and board designs. The unique design inside the SELECT Synchro system increases throughput by reducing the time spent conveying boards. Multiple solder pots can be configured, and the system balances the whole process for efficiency and flexibility to deliver solder joint reliability.

- Synchro standard for boards up to 98.4 in. (2,500 mm) long and up to 18.1 in. (460 mm) wide

- Synchro XL for boards up to 98.4 in. (2,500 mm) long and up to 26.8 in. (680 mm) wide