Offering the lightest-weight in its class, the B-Series cordless torque tool line now offers two battery-powered, transducerized, wireless options for threaded fastening assembly: the B12LA Right-Angle Torque Tool and the B12LB Inline Torque Tool.

All tools are equipped with a STANLEY 4 Amp hour 20V Max Lithium Ion Battery Pack and provide optional battery packs in 2 and 6 Amp hour sizes to optimize power and weight requirements based on the user’s application.

The new B12LA Right-Angle Torque Tool is ideal for angled joints and operates in the 400- to 840 RPM range with up to 8, 11 or 16 Nm of torque. It has a 3/8-in. square drive (SD) standard output with optional ¼-in SD, ¼-in. quick change (QC) chuck or flush angle, depending on the model. The tool weighs 2.3 lb. without a battery pack.

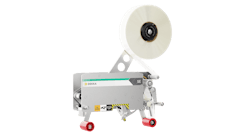

Designed for narrow spaces or inline applications, the new B12LB Inline Torque Tool operates in the 600 to 1265 RPM range with up to 5, 8 or 11 Nm of torque. It's delivered with a ¼-in. quick change (QC) output. The B12LB weighs 1.8 lb. without a battery pack.

These, and all STANLEY B Series Cordless Torque Tools, feature an autonomous operation mode with programming via a Micro-USB port. An internal 802.11 a/b/g/n 2.4/5 GHz wireless controller within the tool manages 16 jobs, 16 tasks and 4 steps. The Tool can store up to 500 fastening cycles and one trace. This allows operators to access trackable information to ensure they are putting the right torque on the fastener.

The B-Series is an extension of the STANLEY QPM DC electric torque tool family and offers a full range of configurations. STANLEY cordless tools are ideal for hard-to-reach, enclosed, overhead applications; interior assembly and installations; electronic assembly benches; and repair and rework stations. All models feature closed-loop transducer control and a brushless, electric DC motor for high performance and reliability.