2-in-1 Dispenser Reduces Waste

Mixpeel, an adhesive packaging and dispensing solution, fits two components in a one-component style cartridge. Customers can benefit from the ease of use, improved filling procedure, additional fill volume, reduced waste volume, and enhanced performance.

The system features the company’s latest 2-in-1 concept, particularly for the construction sector. It can be used for a wide variety of applications such as chemical anchoring, 2-component sealing, crack repair, etc.

Mixpeel provides key benefits to fillers as well as adhesive manufacturers. The design enables both, to more easily and quickly fill the cartridge from either the nose or the backend. For nose filling, pistons come pre-inserted which streamlines the process. When it comes to the 280ml fill volume, Mixpeel provides additional capacity versus competitive products in the market. Finally, the retained waste volume is much lower, compared to other products, which provides environmental benefits.

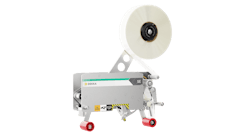

Sulzer Mixpac offers its 1:1 280mL Mixpeel system with a wide range of one-component dispensers offered from the COX and MK range. The Mixpeel package combined with the dispenser as well as the Sulzer MIXPAC mixer portfolio allows the users to benefit from a proven system that is wholly engineered by Sulzer Mixpac to provide superior quality and optimal mixing performance for their applications.

Features:

- 2in1 cartridge with cutter unit inside

- Simple smart design

- Strong barrier properties

- Precise ratio control

- High filling volume

- Separated outlets

- 1-step fitted closure

- Compatible with Mixpac mixers and dispensers

- Especially with Mixpeel 1:1 280mL

- Bigger outlets through new side-by-side design

- New outlet geometry (decentralized)

- Higher filling volume

- Less packaging waste