On-Machine Tool Measurement

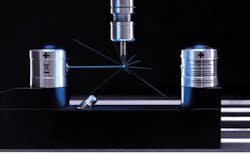

The latest non-contact tool setting solution, NC4+ Blue system, features the industry’s first blue laser technology (patent pending) and improved optics. The system delivers significant improvements in tool measurement accuracy, ensuring components can be machined more precisely and with reduced cycle times.

Compared to red laser sources found in conventional non-contact tool setters, blue laser technology has a shorter wavelength, resulting in improved diffraction effects and optimized laser beam geometry. This enables the measurement of very small tools while minimizing tool-to-tool measurement errors – a critical consideration when machining with a wide range of cutting tools.

NC4+ Blue systems also use Renishaw’s latest non-contact tool setting software packages, which include a new dual measurement mode with auto optimization technology. Combined, these features ensure fast and reliable tool measurement – even in wet conditions – saving users time and money.

NC4+ Blue support is now embedded into Renishaw’s extensive range of graphical user interfaces, including on-machine and mobile apps such as Renishaw Set and Inspect, and GoProbe. These consistent, easy-to-use programming platforms are perfect for users who are new to probing or have little machine code knowledge, while still offering operational benefits to more experienced users.

Renishaw technologies provide data that enables intelligent decision-making for Industry 4.0. On-machine tool measurement allows manufacturers to automate and optimize their processes and minimize quality problems and CNC machine stoppages. With the latest version of Renishaw’s on-machine Reporter app, users can now view historical tool data captured by the NC4+ Blue and export the results for use in their chosen software and control systems.