PopPick goods-to-person solution pairs an upgraded moveable shelf carried by mobile robots with the industry's first dual-unit picking station. As an all-in-one solution, PopPick combines picking and storing totes, shelves, and pallets.

Able to handle goods of any size and varying configurations, PopPick is ready for anything and has eliminated the tradeoff; picking efficiency, storage density, worker safety, and fast return on investment are all possible with this all-in-one solution.

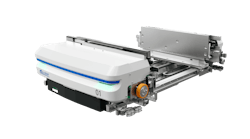

The PopPick workstation is the command center of the system, with the warehouse operator controlling Geek+’s P-series picking robots that ferry racks of goods to the workstation. The operator views the orders on the screen and takes the retrieved goods from the station’s robotic arms, which present their cargo in an ergonomic position for user comfort. With advanced AI and smart autonomous mobile robots (AMRs), PopPick can increase warehouse picking efficiency to up to 650 totes per hour and optimize throughput capacity by a factor of 2 due to its double robotic arms.

The solution uses P series AMR picking robots to move the inventory shelves and pallets to the picking station, completely eliminating walking for picking workers, improving accuracy, and reducing labor intensity.