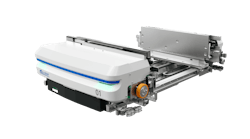

The Ledger A3 high-density automated storage and retrieval system (AS/RS) features high-speed, simultaneous loading and unloading of four front hook trays used for storing, picking, and sorting small, lightweight goods.

Designed to provide maximum storage and retrieval at high speed for high-throughput distribution applications, the Ledger A3 travels 984 ft/min (300 m/min), lifts 360 ft/min (110 m/min), and handles weights up to 15 lb./tray (7 kg/tray) or 60 lb/four-quad carriage (28 kg/four-quad carriage).

This mini-load doubles the storage/retrieval capacity of a conventional mini-load AS/RS that typically offers 1 or 2 deep storage. The A3 (11.7 x 16.5 in.) 4 quad trays move individually or simultaneously, sorting small items at large capacity and at scale with unfailing precision. By simultaneously loading and unloading each of the four front-hooked trays, it delivers double the capacity compared to a conventional mini-load AS/RS with one or two deep storage, moving 400 trays/hour and improving storage capacity with 1.3 times more efficiency than the conventional AS/RS.

Together with Muratec’s rail-guided, bi-directional case sortation loop or “SHUTTLINER,” the Ledger A3 can operate as a goods-to-person (G2P) system enabling minimal material handling, further boosting throughput.

The Ledger A3 has had multiple successful implementations in high throughput warehouse and distribution environments moving small goods in the medical & pharmaceutical, cosmetics, and food & beverage sectors.

- Twice the loading/unloading capacity (400/hr) of conventional mini-load AS/RS

- Over 1.3 times higher storage efficiency over conventional mini-load AS/RS

- Combines with rail-guided shuttle conveyance for an efficient G2P system

- Uses a dedicated tray

- Weight Capacity: Max 15.4 lb. (7 kg) × 4 Tray

- Size Capacity (W x D x H): 13.4 x 18.9 x 11 in. max (340 x 480 x 280 mm)

- Crane Installation Height: Max. 29.5 ft (9 m)