ADAPTO: Scalable, Automated AS/RS System (V 3.3)

2022 NED Innovation Award Finalist

The third generation of ADAPTO—a roaming shuttle automated storage and retrieval system (AS/RS) with highly advanced sorting and sequencing capabilities—automates the picking of a wide array of products to serve as a force multiplier for staff members and enabling distribution centers (DCs) to operate with greater efficiency.

Unlike other shuttle systems, operators can be trained in a matter of minutes to process more orders with fewer mistakes. Since ADAPTO roams levels and aisles independently of lift platforms for true one-to-one picking, accuracy is ensured and orders are never accidentally combined. The system also handles the variety of carton, tray, and tote sizes used in most DCs.

ADAPTO’s small footprint also increases the storage capacity of DCs, allowing the ability to stock more SKUs and increase the overall velocity of fulfillment operations. In addition, ADAPTO seamlessly integrates with Vanderlande’s intelligent software, goods-to-picker workstations, and robotics. Due to its modular design, DCs can scale shuttles and capacity with ease.

- Built-in sorting and sequencing with multidirectional shuttles

- No requirement for additional equipment

- Throughput and storage are independently scalable; ADAPTO facilitates modular applications

- No single point of failure

- Shuttles can be maintained offline

Includes:

- Racking structure with integrated shuttle track

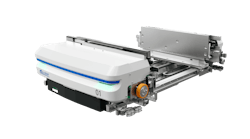

- Multidirectional shuttles

- Shuttle lifts

- Tote/carton lifts

- Traffic control software

- Control and monitoring software