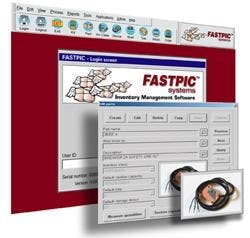

FastPic4 inventory management software automatically displays a photo of the item the operator is required to pick, increasing accuracy rates to 99.9%. In industrial product operations, where accuracy levels are critical, the FastPic photo database feature helps reduce operator error. Once an image of the part is uploaded to the software, every time that part is required for picking, the software displays a thumbnail photo of the item automatically. When needed, the operator can enlarge the photo with a simple click. For replenishing inventory, this feature can be used to visually verify SKU’s, increasing operator productivity by eliminating the need to verify part numbers. The photo inventory feature is particularly valuable in assembly, cycle counting, quality control and replenishment operations. For industrial product operations that use seasonal workers or experience high turnover, the photo inventory database can be used as a tool to reduce training time while increasing accuracy and throughput. FastPic4 software is designed to manage virtually all manual and automated storage and retrieval systems including shelving and rack, pick-to-light, horizontal and vertical carousels and vertical lift modules. The software can also manage multiple workzones where several different types of storage and retrieval systems are used.Designed to be installed quickly and cost effectively, FastPic4 can be used in a stand alone installation or integrated system. A suite of middleware and custom interfaces allows FastPic4 to easily communicate with most existing host WMS and ERP systems. Features such as bar code scanning, bulk storage management, paper pick lists, pick banding, continuous batch picking, and a myriad of supervisory reports and other optional features are also available. FastPic4 is compatible with Windows NT, 2000 and XP. The software includes a how-to demonstration program and offers full HTML documentation.