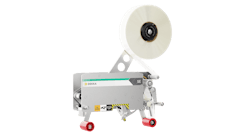

The new DriveTack™ fastening system from Gripnail makes it easy to secure nameplates to metal structures and housings cleanly and permanently with minimal effort. Users can devise an attachment process that fits their exact requirements from several attachment tool options and a wide range of fastener types. According to Dave Ashton, President of Gripnail, "Dataplate attachment is usually the very last step in the manufacturing process and the attachment process is rarely evaluated until it causes problems. The manufacturer's customers, on the other hand, may take notice quickly if poorly attached dataplates detract from the perceived quality of the product or inefficient attachment procedures delay product deliveries. Gripnail's DriveTack can make sure that potential problems like these never materialize."The DriveTack System was designed for fastening nameplates to metal structures such as machine frames, valve bodies, and pump housings. A DriveTack is similar to a Type U drive screw, with two important differences: The head of the DriveTack is flat so that it can be applied with a hand driver or air tool. The point of the DriveTack is tapered to quickly align the hole in the nameplate with the hole in the metal structure.To fasten a dataplate the user simply places the DriveTack on the magnetic tip of the hand driver or Gripnail's 221 low impact air tool, which securely holds the fastener during application and aligns the nameplate holes with a tapered position point that works like a drift pin. A secure fastening is created when the DriveTack's helically knurled shank cuts into the base material.DriveTacks will fasten into any solid material with the proper size hole. They are best suited for cast iron, steel, aluminum and hard plastic. Standard DriveTacks are manufactured from carbon steel and are bright zinc plated. They will pass a minimum of 120-hour salt spray test in accordance with ASTM B117. DriveTacks may also be manufactured from different materials in a wide variety of sizes and platings to meet special assembly requirements.