For Effective HVAC, Knock the Scale Back

The most industrious of insects—bees—use the hexagonal honeycomb pattern to fortify their stores of honey and eggs. Humans have mimicked the bee’s architectural blueprints for thousands of years for its sturdiness and frugal use of materials, though in most instances, they would rather do without the innate storage capabilities. What goes in does not come out without a fight.

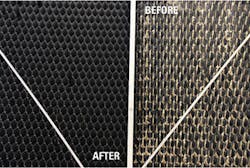

This is never truer than with cooling tower fill, the giant vertical outdoor surface where the heat exchange for an air conditioning system takes place. The intricate geometry allows water to slowly drizzle down as fans blow air through the pores. This dissipates the heat, enabling heat transfer to occur. It also presents a maintenance nightmare.

“That fill has always been a really tricky thing to clean,” explains Tim Kane, president and CEO of Goodway Technologies. “Fill is usually a foot thick to a couple of feet thick, and you can’t look through it, even though it looks like it has these wide open pores.”

These labyrinthine towers could reach 15 feet in height and span 20 feet across, and because they are exposed to the elements, they act like a one-way sponge for anything that comes their way.

“You really get the trifecta of cleaning challenges, because you get three types of contaminants in there: dirt and debris; biological growth that needs to be killed; and thirdly, depending on the quality of water going in there, mineral deposits, or limescale,” Kane says. “Some buildings have one or two, and some poor guys have all three.”

Vacuuming up the dirt and debris every few weeks in the basin of the tower will keep them from entering the system, and a biocide, or a bleach and water mixture, will kill germs, Kane says. Finding a way to break up the scale, though, “was the Holy Grail among chemical companies."

That’s because not only was scale nearly impossible to clean off a vertical surface, it could insulate and protect deadly bacteria such as Legionella deep within the fill’s deep recesses, as was the case in the Bronx last year. The outbreak infected 120 people, proving fatal in 12 instances.

Another important issue is that any insulation in the heat transfer surface makes the cooling system inefficient. Goodway reports that an older 20-story office building saved up to $20,000 a month by bolstering its maintenance by regular vacuuming, cleaning the ducts and coils, and installing a sand filter.

Fortunately, the Connecticut-based Goodway had been developing its ScaleBreak-Gel and the TFC-200 Cooling Tower Fill Cleaner for nearly three years and had just released both to combat the problem, finding a way to make the impossible just one another routine HVAC maintenance procedure.

Their phone was ringing off the hook thanks to their dedication to innovate a product to help their 55,000 customers.

To find this Holy Grail, Goodway’s team of chemical engineers didn’t have to overcome Knights of Templar trials or suffer the Knights who say "Ni." They did, however, have to find a chemical recipe that meets very specific criteria.

“The challenge is that in the process of melting calcium deposits, an outgassing takes place,” Kane says. “It needs to be able to breathe. It has to react with the atmosphere. We had to find the narrow viscosity window where it would stay on long enough to begin the process, but light and thin enough to run away so the outgassing would happen.”

Two years into the development and a lot of trial and error, the chemical engineer strode out of the lab with a smile on his face and boasted, “I’ve got it,” Kane recalls.

“It’s one thing to have success in the lab, it’s another to get out in the field,” Kane says.

The company spent a year testing in various environments, even in the middle of the ocean, to ensure the gel consistently removed the scale. After that, the delivery system, the two-pump TFC-200 was developed.

The water pump operates at 3 GPM at 300 psi to provide a pre-rinse. The gel is applied like spray paint at a rate of 0.5 GPM at 200 psi. Then after about an hour, another 300 psi rinse should aggressively knock the scale off.

As cooling tower cleaning is still at the forefront of everyone’s minds, Goodway looks to capitalize on its innovation gambit.

Kane likens the mission to America’s race to meet John F. Kennedy’s promise to land America on the moon.

“It was too significant an area of opportunity from a business standpoint, and it was a pain point for our customers, Kane says. “It went to the top of the list. We had to get this figured out for our customers in the next couple of years.”