Designing and manufacturing electric motors is taking a few steps forward thanks to continuing work by ECM PCB Stator Technology—developers of a patented technology for printed circuit board stators, and of software for designing, modeling, and prototyping those stators. With those resources, an “ultra-light, premium efficiency” pump motor was designed and manufactured in collaboration with a global pump manufacturer, offering a lighter alternative that meets or exceeds users’ performance expectations.

Electric motors are critical in manufacturing operations (including CNC machines), and also in commercial and residential uses. But motors can be a performance liability too: outdated and inefficient electric motors waste energy and contribute to excess maintenance and operating costs.

Pump manufacturing is a significant part of the market for electric motors, with annual demand valued at more than $200 billion and over 1 billion units. That’s the opportunity available for ECM PCB Stator Technology.

“Though often overlooked, electrically powered pumps are an integral component to millions of commercial and industrial systems. Pump motors are also in drastic need of a 21st-century design upgrade,” explained ECM CEO Brian Casey.

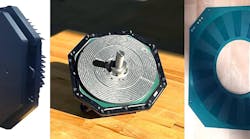

A stator is a stationary component of a rotary motor; when the stator is energized, it spins the motor shaft to add a specific speed and torque that powers the machine. Conventional electric motor technology uses copper windings to conduct the power that is generated, but ECM’s innovation is a much lighter, printed circuit board. When energized via a DC supply and through the motor’s controller, the stators spin a motor shaft to power a machine—in the latest case, the pump.

In addition to lighter stators, the new 3-hp pump motor benefitted from ECM’s PrintStator CAD platform, which is available to customize components for particular motor designs.

According to details provided by ECM, the 3-hp PCB Stator pump motor achieves an efficiency rating of 94%, which is 2.9% higher than market-leading options. Also, at 22 lb. (10 kg) the ECM pump motor is 68% lighter than alternatives and requires 66% less copper.

The developer also reported that its new motor has a “superior form factor with an axial length of 4 in. (100 mm) versus an axial length of 17 in. (424 mm)” for the alternative.

And ECM noted that the same approach to motor design would offer power-conserving and maintenance advantages for motors used in heating, cooling or condensing while addressing performance and sustainability targets in industrial, commercial, and residential applications.

PCB Stator Maximizes Motor Efficiency originally appeared on American Machinist, an Endeavor Business Media partner site.