ZYGO CORPORATION has partnered with Adcole Corporation to offer advanced measurement and inspection technology for automotive camshafts and crankshafts. The latest Adcole system – the Model 1000 Z - incorporates Zygo’s optical sensor technology for precise and quantitative 3D metrology of precision-machined surfaces, without contact at high speed, for optimal process control.

Zygo is a unit of the Ametek Ultra Precision Technologies Division, a supplier of optical metrology solutions, high-precision optics, and optical assemblies used in scientific, industrial, and medical applications.

The Adcole surface finish inspection machine offers expanded metrology capabilities, higher precision, and improved system performance.

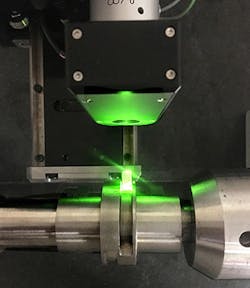

Based on Zygo’s proprietary optical scanning and profiling technology, the new system allows non-contact and 3D measurement of surface roughness, waviness, and other features of precision-machined surfaces on camshafts and crankshafts, with superior accuracy and repeatability in machining environments.

“We are pleased that Adcole selected our technology to integrate into its next-generation system, which will deliver unique capabilities and performance not available in the market today,” according to Michael Schmidt, market development manager for Zygo.

“With the need for higher-efficiency engines and drivetrains, automotive components require surfaces to be machined and controlled to tighter tolerances in the foreseeable future.”

Learn more at www.zygo.com