A fuse is simple in concept: Current flows through a thin metal wire, and when that current gets too high, the metal heats and melts, breaking the circuit. Due to the requirement of melting metal, a fuse is temperature-dependent. A fuse in an oven or furnace will blow with less current, while the same fuse in a very cold environment might take several times or even decades more current to blow then when it’s at room temperature.

Another complication comes from the way that the fuse blows. If there’s a slight overcurrent, it may take minutes for the fuse to finally melt and go open-circuit. If there’s a 1,000-A short-circuit that blows the fuse, then the metal will vaporize, pretty much exploding inside the insulating envelope (Fig. 1). The thin vaporized metal on the inside of the fuse can form an alternate path for high voltage.

1. This fuse has blown quickly enough so that a metal film deposited on the inside of the glass tube. At high voltages, this film can carry current. (Courtesy of flickr)

High-voltage fuses are made to prevent this conductive film from forming when the fuse blows. In addition to ensuring the fuse will break a high-voltage circuit no matter how fast or slow the fuse blows, a high-voltage fuse must have creepage and clearance distances between its terminals that meet safety ratings.

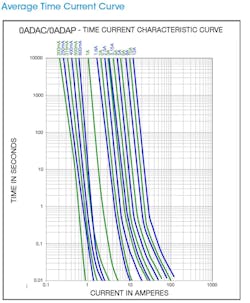

A fuse is a very analog component. Its behavior is best considered by examining the time vs. current charts (Fig. 2). This particular fuse has a characteristic whereby a 1-A fuse would blow in 0.1 sec. when passing 6.5 A. When passing 1 A, the fuse takes 10,000 sec., or 2.7 hours. This is for the ideal production fuse; you can expect manufacturing tolerances to apply so that there’s a band of operation due to part-to-part variation, on top of the inherent temperature sensitivity of fuses.

2. The time-current curve describes how fast a fuse will blow at any given current. It has a log-log scale. (Courtesy of Bel Fuse)

Fuses come in different speed ratings. You may want a slow-blow fuse if the circuit has frequent inrush or high-current events in normal operation. This might be the case if you’re rectifying an ac voltage and storing energy in large hold-up capacitors. When you energize the circuit, there will be a large inrush of current as the capacitors charge up. You don’t want this event to blow the fuse, so you juggle the speed and rating of the fuse to avoid nuisance failures.

Fire Prevention

A major reason for fusing circuits is to prevent fires. Whatever current and speed rating you choose, you must ensure that no circuit board trace, wire, or component will catch fire before the fuse blows. It’s very important to fuse electrolytic capacitors that might catch fire when they dry out and short. You can intentionally design in a narrow circuit board trace to serve as a fuse, but that’s not ideal practice. The copper circuit trace has a large temperature coefficient, and when the “fuse” blows, it ruins your circuit board.

What’s better is to solder in a 1206-sized surface-mount fuse. They don’t take much more space than the trace itself, and fuse experts have designed them to work. If the electrolytic capacitor shorts, you have to solder in a new one. Therefore, it’s preferable to also solder in a fuse rather than having to solder in a jump to the circuit board trace, which will also diminish or destroy the trace’s action as a fuse.

When a fuse blows, an arc forms. The higher the voltage, the longer the arc can be while sustaining current through the metal ions vaporized in the air. This makes high-voltage fuses a specialty. Since an arc gets extinguished 50 or 60 times a second with an ac circuit, voltage ratings for some fuses are different for ac and dc voltages.

To prevent the high-voltage arc from propagating along the inside, high-voltage fuses typically use a white ceramic for the insulating tube, as opposed to clear glass. The opaque nature of the fuse makes it harder to see if it’s blown, but it’s necessary to achieve a high-voltage rating. Here are five high-voltage fuses you can consider in your next project:

1. The 0ADBC1000-BE from Bel Fuse is a 1-A fuse rated for 1000 V. It comes in a 3AB/3AG size, which is 1/4 × 1-1/4 in.

This Bel Fuse 3AG fuse uses a ceramic envelope to achieve a 1000-V rating. (Courtesy of Bel Fuse)

2. The 0508001.MXP from Littelfuse is a 1-A fuse rated for 1000 V. It comes in a 3AB/3AG size, which is 1/4 × 1-1/4 in.

A Littelfuse 1000-V fuse has a ceramic tube. The current, voltage, and speed rating, as well as the safety certifications, are embossed in the metal terminals. (Courtesy of Littelfuse)

3. The 8020.5011.G from Schurter is a 1-A fuse rated for 1000 V. It comes in a 3AB/3AG size, which is 1/4 × 1-1/4 in.

A Schurter 1000-V, 1-A fuse has a ceramic tube with the ratings marked on it. (Courtesy of Schurter)

4. The BK1-S505H-1-R from Eaton is a 1-A fuse rated for 400 V dc and 600 V ac. It comes in a 5- × 20-mm size.

An Eaton fuse in the smaller 20-mm size has a voltage rating of 600 V ac and 400 V dc. (Courtesy of Eaton)

5. The SF-3812TM125T-2 from Bourns is a 1.25-A fuse rated for 250 V dc and 600 V ac. It comes in a surface-mount 10.10- × 3.10- × 3.10-mm size.

A computer rendering depicts a Bourns surface-mount high-voltage fuse with a 25-V dc and 600-V ac rating. (Courtesy of Bourns)

If you need to protect a high-voltage circuit in your next design, be sure to check out these parts.