Every industrial hose assembly must effectively control two basic internal forces, working pressure and end force. Both forces are present in all industrial hose assemblies and represent a unique challenge and danger when not controlled.

Working Pressure is defined as the force applied to an object perpendicular to the surface. Therefore, inside a chemical hose assembly working pressure is defined as the force that is trying to break through the walls of the hose. Typically, hose manufacturers will build in a safety factor which is based on the published working pressure of the hose. Depending on the hazardous chemical being transferred most safety factors are either 4 or 5 to 1.

For example the LPG industry mandates that the hose and hose assembly must meet a 5 to 1 safety factor. Since LPG hose is rated at 350 psi working pressure the hose and hose assembly must burst at 1,750 psi or higher in order to maintain the 5 to 1 safety factor.

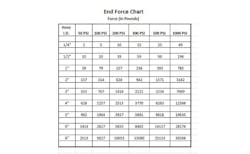

The second dynamic found in all industrial hose assemblies is called end force. End force is defined as the force that travels longitudinally along the hose assembly and is actually trying to force the fitting out of the end of the hose. End Force is the product of working pressure x cross sectional area. Note that in 1 ½-in. ID hose and larger the end force is always greater than the working pressure, conversely in 1 ¼-in. ID hose and smaller the end force is always less than the working pressure.

From the end force chart we can determine that a 2-in. Chemical hose that is operating at 300 psi working pressure creates an end force that is equal to 942 lb. Understanding the different dynamics with in the hose assembly gives us insight into why they are considered the weak link.

If plant safety is directly related to layers of protection and the hose assembly represents the weak-link in all transfer operations, then it makes good sense to add a layer of protection inside of the hose assembly. Smart-Hose Technologies Any Hose, Any Fitting, Any Application we can make all transfer operations safer!