Kobe Steel Ltd. reported that its high-strength steel material for producing intermediate shafts for ships has been adopted by the International Association of Classification Societies (IACS) under Unified Requirements (UR). Nippon Kaiji Kyokai (the Japanese ship classification society, known as ClassNK) last year qualified the steel forged product as a “special approved material.”

Kobe Steel also has a process for producing large-scale crankshafts for marine diesel engines, involving die forging the near-net-shape “throws” of the crankshaft, rather than the roll forging, casting, or machining, which are more standard production methods.

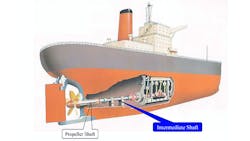

The intermediate shaft is the element of the marine drive train that links the crankshaft to the propeller shaft, and transmits power from the engine to the propeller.

The current design direction for large seagoing vessels calls for large propellers that rotate slowly, which means the drive system must achieve higher output to offset the lower rotating speed. As noted by Kobe Steel, ship designers of now seek engines with low-speed, high-torque rotation in order to achieve high output and high efficiency. A high-strength intermediate shaft is required to contain torsional vibration when the engine rotates at low speed.

Kobe Steel’s innovation in intermediate shaft design stems from its own development in high-strength steel materials. The standard material for such shafts had reached a limit, the steelmaker explained, as under IACS UR standards the material design for intermediate shafts had a maximum tensile strength of TS800N/mm2.

Because Kobe Steel is able to produce high-strength steel up to that tolerance, ClassNK proposed to the IACS that the material be approved for UR, which led to it being adopted for UR up to TS950N/mm2.

Now, under the IACS UR, it is now possible to design intermediate shafts of higher strength, and with the same diameter, thus making them better able to manage large torsional vibrations. “From the standpoint of the same torsional vibration stress, intermediate shafts of smaller diameters are also possible, saving on weight,” according to the steelmaker.

Kobe Steel’s casting and forging business supplies numerous ship components, including built-up and solid crankshafts, intermediate shafts and propeller shafts. Such parts are inspected and assured with exacting quality controls, including the Automatic Ultrasonic Test (AUT) and quantitative digital evaluation of the contact area of crankshafts.