Shigeo Shingo, then an industrial engineer at Toyota Motor Corp., introduced the concept of poka-yoke (pronounced POH-kah YOH-kay) in 1961. Shingo's initial term was baka-yoke, which means "fool-proofing." In 1963, a worker at Arakawa Body Co. refused to use baka-yoke mechanisms in her work area, because of the term's dishonorable and offensive connotation, and subsequently, the term was changed to poka-yoke, which means "error-proofing" or "mistake-proofing."

What is Poka-Yoke?

A mistake is the execution of a prohibited action, the failure to correctly perform a required action, or the misinterpretation of information essential to the correct execution of an action.

Poka-Yoke involves using process or design features to prevent the manufacture of a "non-conforming" product. It may also be a process improvement system that prevents personal injury, promotes job safety, prevents faulty products, and prevents machine damage.

In other words, Poka-Yokes are mechanisms used to mistake-proof an entire process. Ideally, Poka-Yokes ensure that proper conditions exist before actually executing a process step, preventing defects from occurring in the first place. Where this is not possible, Poka-Yokes perform a detective function, eliminating defects in the process as early as possible.

Many people think of Poka-Yokes as limit switches, optical inspection systems, guide pins, or automatic shutoffs that should be implemented by a plant's engineering department. This is a very narrow view. Poka-Yoke mechanisms can be electrical, mechanical, procedural, visual, human or any other form that prevents incorrect execution of a process step.

Also, Poka-Yokes may be implemented in areas other than production such as sales, order entry, purchasing or product development, where the cost of mistakes is much higher than on the shop floor. The reality is that defect prevention, or defect detection and removal, has widespread applications in most organizations.

Mistake-proofing can be defined as designing the process to prevent mistakes from occurring, to stop an error from occurring during further processing, to warn that the error has occurred, etc.

Error-proofing has these meanings as well, and might also include taking measures to prevent assembly errors, such as adding design features to prevent upside-down, backward or reversed assembly; using snap-together features to eliminate fasteners (eliminating missing fasteners, incorrect fasteners, fasteners applied with too high/low torque, etc.). Most people use the two terms interchangeably.

Error-Proofing

There can be three approaches to error-proofing: physical, operational, and philosophical.

- The physical approach involves installing components, like fixtures or sensors, to eliminate conditions that may lead to an error.

- The operational approach involves making modifications or installing devices that reinforce the correct procedure sequence.

- The philosophical approach involves identifying situations that cause defects and doing something about it. This involves empowerment of the workforce.

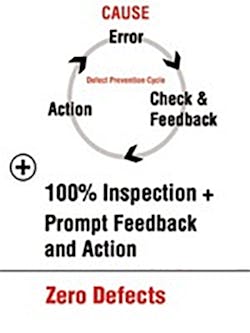

Error-proofing can be implemented by detection and by prevention, too: "Detection" means identifying defects and immediately initiating corrective action to prevent multiple defects from forming; "prevention" means stopping the errors from occurring and creating defects in the first place.

A defect is the result of any deviation from product specifications that may lead to customer dissatisfaction. There are two ways a product can classify as having a defect:

- The product has deviated from manufacturing or design specifications

- The product does not meet internal and/or external customer expectations

An error is any deviation from the specified manufacturing process. There can be an error without a defect, but there cannot be a defect without an error.

Error-proofing as it's understood and practiced today is an outgrowth of the quality movement, specifically the "Zero Defects" initiative. It's a team-based, plant floor improvement strategy that focuses on production processes and operations. Error-proofing aims to prevent errors and deviations from standards of all kinds that can impact quality, safety, manufacturing costs, and customer satisfaction.

Design/Process FMEA and Error-Proofing

A Design Failure Mode Effects Analysis (DFMEA) is an analytical technique used by product or process designers to ensure that, to the extent possible, potential failure modes and their associated causes have been considered and addressed. The design must be improved based on the results of the FMEA study. All design details and possible error-proofing steps should be identified during the development of DFMEA, and integrated into the design.

All the manufacturing/process issues are prioritized to help identify opportunities for the greatest impact, for the customer, and for return for investment. The tool most commonly used to identify/prioritize the issues is Process Failure Mode and Effects Analysis (PFMEA).

The PFMEA method is used by cross-functional teams to answer all process-related questions and to quantify the results in the form of a Risk Priority Number (RPN). The PFMEA tool helps the team to ask key questions toward identifying and implementing error-proofing, to improve the process.

Error-Proofing Techniques

There are a number of widely accepted techniques to carry out effective error-proofing, including:

- Design for Manufacturability (DFM): This technique refers to designs that can not be incorrectly manufactured or assembled, and it also may be used to "simplify" a design, and therefore reduce the production cost.

- Poka-Yoke System: This refers to set-up or inspection techniques that assure a process is set up correctly—i.e., from the first finished part onward, 100% of the output is good quality.

- Design Stage: The best opportunity to impact quality and cost.

Why Use Error-Proofing?

There are demonstrable and persuasive arguments for adopting error-proofing, including:

- Competitive advantage: In a global market the cost of quality is part of the competitive advantage. It costs far less to prevent defects from occurring in the first place than it does to catch them later through inspection and to rework or repair the errors.

- Knowledgeable workers: When every employee understands the principles of error-proofing, work teams can more easily see how defects are generated, and then can effectively eliminate them. They can participate in the design and improvement of parts processing and assembly operations in order to prevent defects from occurring. These methods can be employed in middle and upper management as well, to eliminate errors in paper processes.

- Predictability: If machines (manual or robotic) include error-proofing devices, then the operators are assured that the finished product will be defect-free. This eliminates inspection and rework operations, as well as scrap, all of which increase manufacturing costs.

- Reduced variation: Error-proofing devices ensure that subassembly and assemblies are exactly the same. There will be little chance of part-to-part variation if the machines are designed or modified to prevent errors and the defects that result.

Human Error

Human error is natural, but sometimes when errors can be traced back to the operator's interaction with the process, there is a tendency to blame the operator. We encourage the operator to try harder not to make mistakes, but the root cause of the error is usually failure to account for the possibility of human errors or omissions—by people who design machinery, layouts or operating procedures.

Error-proofing can correct this. It's important to realize that human errors are inevitable, a part of human nature. Few workers make errors intentionally, and most strive to prevent errors. Error-proofing alters the work environment to reduce the opportunity for human errors.

When incorporating error-proofing into the work environment, understanding human limits is essential. These limits include:

- Vision: People vary in ability to distinguish details, colors or adjust vision to lighting.

- Hearing: Individual upper and lower thresholds of hearing change when background noise is added.

- Repetition ability: Muscular efficiency and mental tracking decrease as rates of repetition increase.

In a DMAIC (Define-MeasureAnalyze-Improve-Control) project, this step is usually performed in the Control phase, to prevent a specific defect from occurring. It's next to impossible to reach Six Sigma and Lean Implementation without applying error-proofing concepts.