Latest from Plant Operations

Life is full of opposing views. If you are heading to the beach, then you want to have the “perfect” beach body. This requires a strict adherence to a healthy diet and a strong gym regimen. After a fun day in the sun, you want to relax with friends over a few beers and some great eats. However, relaxing in this manner will change your beach bod into a Dad bod. With worm gear pairs, there's a similar situation. You design the system to achieve a certain speed reduction, at a particular torque load, but the backlash in the system throws off the repeatability of the mechanism.

The usual method of adjusting the backlash of a worm-gear assembly is to modify the center distance. Once assembled, such adjustment requires a major rework of the gearbox housing. One method for eliminating the backlash is to use a spring-loaded split worm or a spring-loaded split-worm wheel. These two styles of anti-backlash worm gear pairs are limited in their loading due to the limitations of the spring rate. However, the use of duplex worm gears allows the backlash adjustment to be made by axially shifting the worm. This greatly simplifies the assembly and maintenance operations.

Because worm-gear pairs are a friction-drive mechanism, it's critical that the worm has a surface strength (durability) that's greater than that of the worm wheel. When the worm reverses rotation, there's a loss in the engagement of the worm-wheel teeth as a result of backlash. When the backlash is minimized by reducing the center distance, there's an increase in wear due to increased contact area.

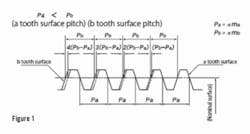

A duplex worm gear pair consists of a dual-lead worm and a corresponding worm wheel. The dual-lead worm is formed to give a difference between the right tooth surface and the left tooth surface, so it provides a unique tooth profile in which the tooth thickness varies continuously, corresponding with the lead difference (see Figure 1).

When such a worm and worm gear are set up at a constant assembly distance and the worm is moved in the axial direction, the tooth thickness of the worm in mesh with the worm gear changes, making backlash adjustment possible.

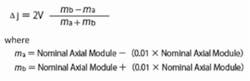

The amount of change in backlash (D j mm) in relation to the axial movement of the duplex worm shaft (V mm) can be calculated from the following formula:

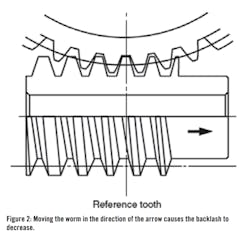

When the worm is held with an arrow mark pointing right, the tooth thickness is thinner on the right and thicker on the left. Therefore, moving the worm to the right causes the thicker teeth to come into actual engagement with the worm gear, thereby reducing the backlash (see Figure 2).

The KHK duplex worm is designed so that, for all modules, the backlash reduces by 0.02 millimeters for each 1 millimeter that the worm is shifted. As the worm wheels are produced with a backlash range of -0.045 to +0.045, a 2-millimeter axial adjustment can result in a zero-backlash pair.

These worm-gear pairs are excellent choices for rotary tables, ultra-low backlash gearboxes, and other high-accuracy reversing applications.

Brian Dengel is the general manager of KHK-USA, which is based in Mineola, New York. Visit them online at www.khkgears.us.