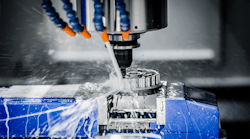

Milling employs rotary cutters, which take out material from a workpiece. The machinist fixes the workpiece at a specific angle to the tool's axis to perform milling.

What is 3, 4, and 5 Axis Machining?

Before understanding which axis machining is the right choice for you, it is essential to understand the fundamentals by delving into their definitions.

3-Axis Machining

The workpiece is kept stationary, with only the cutting tool having a range of motion, which moves along the three axes to perform milling on the workpiece. The process of machining 2D and 2.5D geometry involves the implementation of 3-axis machines.

As the name suggests, 3-axis machining is only operable on three axes, simplifying the milling process. The material gets removed from the workpiece on these three axes, described by back to front, up and down, and side to side.

The only drawback of the 3-axis milling is that it is not competent in designing angled geometrical features to the X-Y-Z coordinate system, irrespective of the feature's planar structure. 3-axis machining is suitable for performing drillings and threaded holes in-line with an axis or creating planar milled profiles.

It is possible to machine a component from all six sides using 3-axis machining, but you will need a new fixturing setup for each side, which is an expensive process. However, if you need a single fixture setup, you should machine only one side of the component.

4-Axis Machining

A 4-axis CNC machine operates on the X, Y, and Z axes and another axis of rotation, which is typically around the X-axis. This fourth axis gets referred to as the A-axis.

4-axis milling works similarly to the 3-axis machining process, where a cutting tool extracts material from a workpiece and creates the desired geometry in the machined part. This machining process is budget-friendly; however, it can also be achieved using a 3-axis machine.

The primary distinction between the two is that, unlike 3-axis machining, the 4-axes machining process provides an additional axis of rotation besides the regular 3-rotational axis. A user can conveniently machine four sides of a component for a single fixture setup.

A 4-axis machine does not demand fixture change-overs and comes with the added benefit that you get tighter tolerances held between features on several sides of the component.

4-axis CNC machining gets classified further into two types -

- Indexing: This process occurs when the fourth axis of the 4-axis CNC machining performs the rotation while the machine is idle and not extracting any material.

- Continuous: This 4-axis machining process occurs when the machine can simultaneously remove material from the workpiece while the A-axis undergoes rotation.

5-Axis Machining

All axes of 4-axis machining, besides another rotational axis, are traversed by the 5-axis machining, which helps achieve sharp precision and refined detailing in the geometry of components.

Several industries demand intricately crafted components to manufacture aerospace machinery, medical tools, car molds, titanium pieces, artificial bones, military stocks, and several others.

You can find the 5th axis of rotation around the Y-axis in the X-Y-Z plane and around the B-axis. The extreme levels of multidimensional rotation and component movement help achieve precision, polished finish, and high delivery speeds. Such precision components are a necessity in industries like aerospace and flight engineering.

With 5-axis machining, you can perform single-step machining, which minimizes lead time and makes it convenient for you to access the part geometry. This machining technique also ensures tool longevity and boosts process efficiency by having the table tilted to perform the precision cutting.

3, 4, and 5-axis Machining - Which One Should You Pick?

As you might have figured out by now, the fundamental difference between 3, 4, and 5-axis machining is in the axis movement that occurs between the cutting equipment and the workpiece. Higher motion complexity between the two parts helps machinists manufacture more geometrically-complex parts for various industries.

The number of axes indicates the complexity of the milling process that the machine can perform, the intricacy levels it can achieve when milling the component, and the points of the workpiece that the machine can work upon.

While there is no one-size-fits-all when in the market purchasing a milling machine, it all boils down to your exclusive manufacturing requirements, the intricacy and precision required, and your budget.

If you need a milling machine to dig holes, a task that does not demand precision, go for a three or 4-axis milling machine. If you supply aerospace components, you must maintain unparalleled precision, which you can achieve only with 5-axis machining. If you wish to create complex 3D shapes or perform milling on tilted surfaces of a component while ensuring high precision, go for a 4-axis milling machine.

Final Words

CNC milling is an immensely efficient process that helps remove material from a workpiece with varying geometrical intricacies. Therefore, you must carefully make a purchasing decision based on your requirements, budget, and work hours.

Most small machine factories do not have to work on intricate geometrical patterns; therefore, a 3-axis machine gets the job done for them. For specialized applications such as working on complex geometries, machinists must purchase a 4-axis machine. If you require ultimate precision in your machined parts and are working on complex and tilted geometries, a 5-axis machine is the one for you.