Latest from Plant Operations

Flying High With Alp Aviation

Our editorial team flew to Eskisehir to talk to Mr. Serkan Erten, Business Unit Director from Engine Business Unit at Alp Aviation and found out about the business fields of Alp Aviation as well as the connection between WFL and Alp.

Interviewer: Mr. Erten, please give us a short overview of Alp Aviation. What is the company’s core competence and which business fields are you operating in?

Serkan Erten [SE]: Alp Aviation is a joint venture with Sikorsky Aircraft, a Lockheed Martin company, established in 1998. Our core competence is for sure the extensive experience in machining and processing titanium, superalloys, aluminum, steel, stainless steel, magnesium, and copper alloys.

Alp Aviation has four facilities in Eskisehir with a total production area of 50,000 m2. Among our clients are the world’s leading aerospace companies, such as Pratt & Whitney, Sikorsky, Collins Aerospace, Honeywell, Pratt & Whitney Canada, Lockheed Martin, and Boeing.

We are mainly selling to North America and Canada, but besides U.S. companies we also deliver to Europe, e.g. Poland, France, and the Czech Republic. The export ratio is about 98%, whereas 90% are being delivered to North America.

For manufacturing, we only have the facility in Eskisehir, where five business units are located. One of Alp’s business units is the Aerostructure business unit. The typical customers are Boeing, Lockheed Martin, Sikorsky well as Collins Aerospace.

The second business unit is the Engine business unit which I am responsible for. We are producing/manufacturing engine dynamic components, mainly for Pratt and Whitney and Honeywell.

At the military level, we are working on the F-135 Engine, and at a commercial level, we are working on the Geared Turbofan (GTF) engines.

Honeywell is an important customer for engine components too. We started to produce tie shafts for their commercial engines. For that purpose, we invested in a complete machining center from WFL—to be more precise, an M40 MILLTURN with a 10-foot (3,000 millimeters) center distance.

The third business unit is the Rotary Wing business unit. Their main responsibility is to provide dynamic helicopter components, gears, gearboxes, and other dynamic components for helicopters.

The fourth business unit is Special Processes. Here we have a huge capability in-house and can do the chemical and mechanical processes by ourselves.

There is also a fifth business unit for landing gears. We are working together with Collins Aerospace and Heroux Devtek on the F-35 program and on other commercial programs for Boeing and Airbus.

What has been the main purpose to invest in a MILLTURN complete machining center of WFL?

SE: I have to start by explaining how our company works. At the moment, we have over 250 machine tools and we are producing a wide range of parts for the Aerospace Industry. Mainly 5-axis milling and MILLTURN equipment are being used for producing those components.

On the M40 MILLTURN from WFL, we only manufacture shafts. The main purpose of the investment was to be at the center of excellence in shaft production for engine producers.

With the MILLTURN, we have become a tie shaft producer for our customers. Tie shafts are a critical component of engines and serve as a connection between the turbine and the compressor.

The length of the tie shafts manufactured at Alp Aviation ranges from about three to six feet (1,000 to 2,000 millimeters). The main materials that are used for the production of tie shafts are Inconel and maraging steel.

We have lots of experience with Inconel production, as we have already started to produce engine components made of titanium or Inconel in 2008. For that reason, we have enough experience with these materials.

With regards to the shafts, we continue to work with Inconel material and high-strength steel.

Can you tell us about the main requirements for investing in a new complete machining center?

SE: To be able to produce dynamic engine components, we need productive and process reliable high-tech machines and outstanding technological performance.

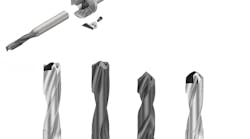

Generally, nickel alloys are commonly used during engine component production. These special nickel alloys are highly heat resistant. That is to say, these materials are extremely rigid, difficult to machine and a high level of technical expertise is required to meet the high-quality standards in the industry.

Which batch sizes are common in your industry and business unit?

SE: In the commercial Aerospace business, the product range varies depending on the commercial platforms. In some cases, we are producing around 600 workpieces per year, depending on the size of the commercial platforms. The medium volume of production ranges from 200 to 300 pieces per year. But this is the limit as our industry is not known for automation and large series.

We are not talking about 10,000 pieces of workpieces per year; in the Aerospace Business, the maximum volume is around 1,000 pieces per year.

Which machines or processes were replaced upon the purchase of the M40 MILLTURN?

SE: With installing the MILLTURN we started to produce larger shafts for the first time. That means we only bought the machine to be able to produce bigger shafts.

Up to this point in time we only manufactured smaller shafts starting from 10 to 19 inches (250 to 500 millimeters) in length on rather small machines. When we received drawings for bigger and longer shafts we established contact with WFL, because we knew that WFL has a very good reputation in the Aerospace industry.

Now we are producing about 200 shafts per year.

What are the technological possibilities with the M40 MILLTURN?

SE: With the implementation of the M40 MILLTURN we achieved perfect machining performance, high surface quality, high static, and dynamic rigidity as well as reliable and repeatable accuracy. Especially for shaft production, in-process measurement is an important technology to achieve tight tolerances.

We prefer multitasking machines, as there is no need to move parts from one machine to another one. Time-saving was as well an important factor for buying the machine.

What are the main advantages of complete machining?

SE: By doing complete machining on one single machine tool, processing time could be reduced by 30% and an increase in flexibility of 60% could be achieved. Our customers need to rely on our performance, and it is really important to work most efficiently and achieve low lead times.

Can you tell me a little bit more about the manufacturing of the tie shafts in the MILLTURN. It would be interesting to get an insight into the production process.

SE: The production of one shaft, starting with the procurement of the materials up to the finishing processes, lasts around six weeks. This type of shaft requires chemical as well as mechanical processes, such as heat treatment, shot peening, chrome plating, silver plating, grinding or balancing.

The six weeks refer to the entire process. The fact that the whole process can be done in-house is the main power and strength of Alp Aviation in order to convince the customer’s needs.

What are the future strategies of Alp Aviation?

SE: We aim to be at the center of excellence regarding the design and manufacturing of engines as well as fixed-wing and rotary-wing dynamic components.

Furthermore, we intend to be at the center of excellence for the production of shafts.

Alp Aviation has been approved as Research and Development Center by the Turkish Government. This is an important step for gaining even more significant roles in national and international programs as a design and engineering partner. We will be able to be a global subsystem supplier in Design and Production for our customers.

The current topic of Industry 4.0 is circulating in many companies. Which measures did you take with regards to Industry 4.0?

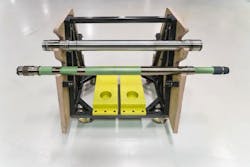

Since the topic popped up, we have been following all the technological developments in the world. A flexible manufacturing system with four machine tools and a centralized tool change system has been established two years ago and thanks to this innovative solution productivity increased by 30%.

Our aim is to reduce labor hours and increase technological improvements. For that reason, all our investments are a base for this approach.

When we made the decision to invest in a MILLTURN, we also discussed this topic and its future development. As soon as the economic situation is getting better and requests are increasing, we will probably invest in further machines as well in automation.

About ALP Aviation

Established: 1998

Located in: Turkey

Employees: 1,300, from that 200 engineers

Industry: Supplier of Aerospace components

Business Units: Aerostructure Business, Engine Business, Rotary Wing Business, Special Process Business and Landing Gear Business

In communication with: Mr. Serkan Erten, Business Unit Director Field: Engine Business Unit

Typical products of ALP Aviation

- Dynamic and Static Engine and APU Parts

- Helicopter Dynamic Parts & Assemblies

- Helicopter Tail Rotor Drive Shaft

- Landing Gears and Assemblies

- Structural Parts & Assemblies for Aircraft

- Hydraulic and Fuel Systems Tube Assemblies for various platforms of Boeing and Airbus.