FieldComm Group Offers Test, Registration Services for Ethernet-APL Infrastructure

FieldComm Group has added Ethernet-APL solutions to its conformance testing and registration services for instrumentation technologies for the process automation sector. It also offers physical layer conformance testing for Ethernet-APL infrastructure products—power switches and field switches.

Ethernet-APL is an enhanced physical layer for single-pair Ethernet (SPE) based on 10BASET1L. This new physical layer provides end-users with a resilient, isolated, and powered Ethernet network for process automation. Ethernet-APL-enabled field devices connect directly to this network. Switches registered with FieldComm Group undergo conformance tests for crucial aspects of the physical layer of the new technology: EMC, Data, and Power.

Gunther Rogoll, Manager of Fieldbus Technology for Pepperl+Fuchs expressed excitement for this milestone. “We are thrilled to have the first registered Ethernet-APL switches, the Rail Field Switches including up to 24 intrinsically safe Ex ic spur ports, with FieldComm Group. We have recently been working with FieldComm Group to create test policies and procedures for infrastructure products like field switches and power switches usable by all test and registration authorities in the Ethernet-APL consortium, including ODVA, OPC Foundation, and PROFIBUS & PROFINET International. This effort will ensure conformance to the Ethernet APL standards independent of the testing agency.”

FieldComm Group has worked closely with ODVA, OPC Foundation, and PROFIBUS & PROFINET International in a concerted collaboration in developing the test specifications and processes for Ethernet-APL products.

FieldComm has developed a conformity assessment system to support Ethernet-APL switching hardware. FieldComm Group assesses products for overall conformity to the Ethernet-APL standards using a combination of test results from specialized laboratories and in-house testing services. Products are evaluated against the latest test specifications to ensure consistent EMC immunity and emissions of products; the functionality of the PMA, PCS, PHY Control, and Auto-Negotiation sublayer; and the correct implementation of Port Profiles electrical characteristics such as noise and power for Intrinsic Safety.

Product owners who submit conformant Ethernet-APL infrastructure hardware receive a conformance report, certificate, and listing on the FieldComm Group Product Registry.

Danfoss Introduces Remote Service Passes

Danfoss Power Solutions, a global supplier of mobile and industrial hydraulics and electric powertrain systems, has introduced remote service passes for its PLUS+1 CS10 wireless gateway. Remote service passes allow machine technicians to connect remotely to a machine with a CS10 device installed to monitor machine behavior, debug, and update firmware over the air.

The passes allow technicians to monitor changes in equipment or operation and set alert triggers to notify stakeholders when a change is detected. The passes also enable debugging. Technicians can access the machine’s CAN data bus over a remote connection to diagnose issues. Another capability is faster machine prototyping. OEMs can get a machine into the field sooner with the ability to remotely update firmware and software configurations.

Read more about Danfoss' latest products...

Remote service passes work with Danfoss’ entry-level CS10 wireless gateway. With these passes, it's now possible to get a global connection by connecting the CS10 device to the internet through a local Wi-Fi hotspot. A single pass lasts for 24 hours and provides unlimited data for virtual service sessions from anywhere in the world using the company’s PLUS+1 Service Tool. The pay-per-use model offers flexibility, enabling companies to use a digital service plan as needed rather than pay for a monthly data plan.

To learn more, visit the PLUS+1 Connect webpage.

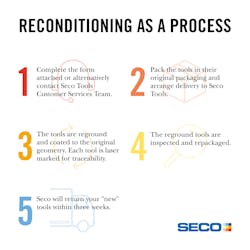

Seco Tools' Reconditioning Service

Seco Tools' solid-round tool reconditioning service helps tools regain 85 to 95% of their original performance compared to tools that are reground or resharpened. Without having to readjust parameters or sacrifice performance, the reconditioned tool performance lives up to today’s advanced machining strategies, for example, in dynamic milling where only a small portion of a tool’s diameter is engaged in the cut.

The regrinding process sharpens a tool’s cutting edges. Seco reconditioning, on the other hand, brings round tools back to a level close to their original condition in terms of properties and performance.

Read more about Seco Tools' latest products and services...

The same process used for new tool manufacturing is applied when Seco reconditions a tool. This includes all relevant grinding steps on the same type of machine with the same programs, wheel types, as well as the reapplication of coatings that were applied when the tool was produced new.

Seco identifies the tool and its reconditioning program that matches all original/as-new specifications and applies all the necessary micro and geometrical properties.

Plus, Seco reconditioning can be applied to the same tool typically two or three times to significantly extend its working life.

Each of these reconditioning cycles, according to Ruud Zanders, Global Reconditioning Lead at Seco Tools, is also done at half to one-third of the price of a new tool.

For more information on Seco tool reconditioning, visit www.secotools.com/reconditioning

Rockwell Automation Offers Endpoint Protection

Rockwell Automation and CrowdStrike are providing manufacturers with comprehensive Endpoint Protection Services, combining Rockwell Automation’s Industrial Cybersecurity Services and CrowdStrike Falcon platform to monitor, protect, investigate, and respond to incidents.

Built in the cloud with a single lightweight-agent architecture, the CrowdStrike platform delivers rapid and scalable deployment, superior protection and performance, reduced complexity, and immediate time-to-value. Customers benefit from unified technology, intelligence, and expertise that delivers security that works across their on-premise, hybrid, and cloud environments.

Read more about Rockwell's latest products and services...

Customers will receive the industry-leading software coupled with OT-specific Falcon policies, developed by Rockwell cybersecurity specialists, and backed by software and phone support.

To learn more, visit Rockwell Industrial Cybersecurity.