Grupo Euskal Forging – a manufacturer of seamless rolled rings and other forged parts — has ordered a new ring-rolling machine from SMS Meer. The equipment builder noted it would be the fifth seamless ring mill for Euskal, and the “second most powerful” ring-rolling machine it has ever built.

The machine will be installed at Euskal’s plant in Sestao, one of its five operations in Northern Spain. Euskal produces seamless rings with outside diameters up to 8,000 mm, as well as open-die forgings like axles, crankshafts, and forged discs.

SMS Meer is a business unit of the SMS Group that designs and builds heavy machinery and performs production engineering for forging and other metallurgical operations.

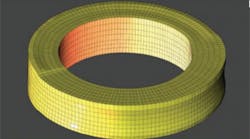

The new RAW 1000 (1250) / 1000 (1250) machine that SMS is supplying will extend its product range to include rings up to 50 metric tons, with a maximum diameter of 10,000 mm, and a maximum ring height of 1,700 mm.

As detailed by SMS, the new machine will allow Euskal to produce large-scale parts like tower flanges for wind turbines as profiled rings, efficiently and cost-effectively. It said the manufacturer would thereby be able to meet market demands for larger rings required for flanges and rotors on larger and taller wind turbines for offshore installations, designed with larger generators up to 7.5 MW.

"The machines and plants from SMS Meer are of a very high quality. They are precise, sturdy and flexible," said Mikel Redin Pérez de Nanclares, the owner of Euskal Forging.

Commissioning is scheduled for the first quarter of 2015.