Simufact introduced the first version of its special module for ring-rolling simulation in 2008. This module made it easy for process engineers to set up the complex kinematics of a ring-rolling process, and then to perform a full 3D simulation in less CPU time than ever before. Simulations that used to take several weeks of CPU time now ran within 1-3 days. The new module was recognized as a breakthrough capability in simulation because, for the first time, it was possible to use simulation as a practical approach to reduce development costs and shorten time to market.

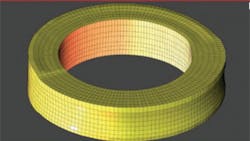

One of the most important capabilities included in the initial version of the ring-rolling module is its so-called “ring mesher”. During a finite element simulation, the geometric shape of the ring is subdivided into small “elements,” and it is critical to do this in the most efficient manner possible. The ring mesher was developed to represent the ring most accurately with a minimal number of elements — which is necessary to reduce the required CPU times to complete a full 3D simulation.

To reduce the required CPU time even further, parallel processing is used. During the simulation, the ring is subdivided into multiple “domains’ and then each domain is simulated on a different CPU. Because the simulation of each domain is done simultaneously, or “in parallel,” the results will be available much sooner. Most of today’s desktop computer hardware employ quad-core, or even sixcore, CPUs. On a computer with two CPUs, each with four cores, it is possible to split the model into eight domains. Simufact.forming is a registered Intel Cluster Ready solution, guaranteeing adherence to the industry standard implementations for High-performance computing.

In order to earn industry acceptance it was critical for the ring-rolling module to be transparently integrated within the regular Simufact.forming environment. This is important because almost all manufacturing processes for a rolled ring consist of multiple steps.

The ring-rolling process typically starts by heating a round or square billet to the forging temperature. Then, this heated billet is upset and a center hole is punched. When the billet is round, these stages of the process can be simulated using the 2D capabilities of Simufact.forming. If the billet is square, these stages are simulated in 3D, but symmetry conditions can be taken into account.

Expanded Results

The next step in the process is the actual ring-rolling operation. If the simulation of the initial stages is performed in 2D, the software can automatically expand the result into full 3D. Then, the ring-rolling operation is set up and simulated using the techniques described earlier.

After the ring-rolling stage, there are often additional operations, like a final pressing of the ring. All this can be simulated as a multi-stage process, using the regular forging simulation capabilities of the software in combination with the special ring-rolling module.

After several important ring manufacturers and ringrolling machine makers used the software for their in-house applications, it was acknowledged that the accuracy of the simulation, the ease-of-use, and the lower CPU-times made it practical to use the simulation to drive their process design decisions. (Further details on the in-house trials are withheld for proprietary considerations, but results from correlation studies are found in a whitepaper available at http://www.simufact-americas.com/ringrolling.)

One important detail that resulted from user feedback was that the software needed to be enhanced to allow simulation of closed-loop processes. Many modern ringrolling machines no longer require the operator to specify the velocities for each roll, but instead make it possible to specify a “higher-order’ input, like a desired growth-rate of the ring diameter. The machines include special measuring devices and the control software of the ring-rolling machine automatically adjusts the process, for example the motion of centering rolls, to achieve the desired higherorder process result.

In order to provide this capability in the simulation environment, the ring-rolling module was enhanced further. The whole machine control algorithm was integrated into the finite element solver, including the required measurement of positions, dimensions and other status quantities. The software architecture is open to implement individual applications, for example, to match a certain proprietary CNC control, but the software is shipped with a set of standard, built-in controls.

The built-in controls are for two of the most common ring-rolling applications: the RAW process and the MERW process. The main difference between these two processes is the mechanism for roll feeding.

In the RAW process, a feed-controlled mandrel is used, while in the MERW process a feed-controlled main roll is used. In both processes, centering rolls are used. The feed motions are based on the diameter of the ring, and must be very carefully controlled to achieve a stable ring-rolling process.

In both RAW and the MERW processes the software automatically calculates the ring diameter during rolling, and the translation speed of any roll can be specified depending on the current diameter of the ring, or a built-in control algorithm can be used to drive these settings.

While ring-rolling operations are implementing these simulation capabilities into their production design processes, the software is being enhanced already for future requirements. Among the future enhancements will be fully integrated heat treatment simulation and the ability to include deformable tools as part of the ring-rolling process. These capabilities are in advanced stages of implementation, and testing and validation are in progress, in collaboration with several research institutes and universities.

| Arjaan Buijk is the managing director for Simufact-Americas LLC. Contact him at tel. 734-238-2173, or [email protected]. The white paper referenced here — Ring Rolling Simulation with Simufact.forming — is available for download at http://simufact-americas.com/ringrolling |

About the Author

Arjaan Buijk

Managing Director

Arjaan Buijk ([email protected]) is the Managing Director of Simufact-Americas LLC