Download this article in PDF format.

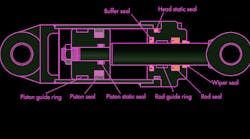

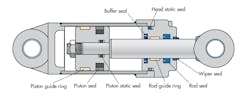

Seals play an important role in hydraulic cylinders—they contain the fluid and prevent the leakage of fluid between components.

They fall into two main categories: dynamic and static. Dynamic seals are used in-between parts that are in relative motion. The seals for a rod sealing system protect the dynamic reciprocating motion for the piston rod and head. The dynamic reciprocating motion between the piston and cylinder bore is another area of a hydraulic cylinder that uses dynamic seals.

Static seals are used between fixed components. In a hydraulic cylinder, static seals are typically employed between the piston and the piston rod, and between the head and cylinder bore tube.

The following is a list of dynamic seals and the special function each has in relation to cylinder performance:

Piston Seals

- They function as a pressure barrier.

- They prevent fluid from passing the piston and are essential for maintaining the position at rest and controlling the motion of the cylinder.

Rod Seals

- They are a pressure barrier and maintain the operating fluid inside the cylinder.

- The rod seal regulates the fluid film, which extends with the surface of the piston rod. This is important to prevent rod corrosion, lubricate the wiper seal, and lubricate the rod seal itself.

- Rod seals also accept the lubrication film as it comes back to the cylinder upon retraction of the rod.

Buffer Seals

- When pressure peaks occur due to excess system pressure, buffer seals protect the rod seal from the pressure rise.

- They improve rod seal performance by attenuating the fluctuations in system pressure. They allow the rod seal to perform with more constant or gradual pressure changes.

- They act as a filter against contaminants that may damage the rod seal.

Wiper Seals

- Wiper seals are important due to their ability to block external contaminants from entering the hydraulic system and cylinder assembly.

- They accept the lubrication film in the cylinder as the rod retracts.

Guide Rings

- Guide rings prevent metal-to-metal contact between cylinder components.

- They keep the piston rod and piston position accurately centered. This is crucial to the performance of the rod sealing and piston sealing system.

- They react against the radial load caused by side loads acted upon the cylinder assembly.

What Causes Seal Failures?

Due to time of use or exposure to abuse, hydraulic seals will eventually fail and need to be replaced. A design engineer may be able to reduce the damage inflicted on hydraulic seals if they keep in mind what typically causes failures, and try to prevent their damaging impact.

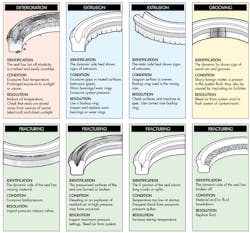

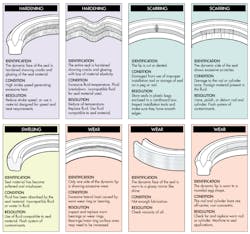

1. Hardening:

Hydraulic seals become hard when exposed to high temperatures. This is caused by either high fluid operating temperatures in the application or high-speed heat generation from stroking operations. When seals harden, they crack and lose elasticity, leading to seal failure.

2. Wear:

Whether due to insufficient lubrication or excessive lateral load, wear on the dynamic face of a seal lip can cause considerable damage.

3. Scarring:

Installation tools and processes are important to the operating life of seals. Improper installation can cause cuts or dents in the dynamic lip of the seal, which affects hydraulic seal efficiency as well as introduces foreign elements into the hydraulic fluid.

4. Fracture:

Fracturing is the condition resulting in burns, breaking, long cracks, and a complete breaking off of the dynamic side of the seal. This is due to excessive backpressure, high-pressure shocks/spikes, or the use of low-grade materials during the manufacturing process of the seal.

5. Improper Installation:

As mentioned before, improper installation can create problems with hydraulic seals. It may result in uncleanliness, unsafe handling, contamination, and incorrect sizing of the chosen seal. Deciding on the seal prior to build is important to make certain that the design is done correctly to ensure proper sealing.

6. Contamination:

The introduction of external flotsam and jetsam into the hydraulic rod causes contamination. When particles such as dirt, mud, powder, or other tiny elements attach themselves to the piston, they dirty the seal. The dirtier the seal, the more it loses its ability to hermetically prevent contaminants from the piston area.

7. Chemical Erosion:

Seal material will break down when it encounters a corrosive fluid. This will occur when the improper seal material is chosen for an application. The use of non-compatible materials leads to chemical attacks by oil additives, hydrolysis, and/or oxidation reduction of seal elements. This will result in the loss of seal lip interface, softening of the seal durometer, swelling, and/or shrinkage of the seal. Discoloration of the seal is an indicator of chemical erosion.

Criteria for Selecting Seals

There are specific design considerations when selecting seals. The right seal for the required application will depend on the application parameters and the information collected from the operating conditions of the hydraulic cylinders. Prior to selecting any seals, one should investigate the following considerations:

- Fluid pressure range: This includes not just the operating range of the fluid system pressure, but also the severity and frequency of the system pressure peaks.

- Temperature range: The resting and operating temperature range of fluid and cylinder assembly are important on seal selection.

- Stroke speed: The velocity of the piston rod’s stroke will impact the seal’s lifetime.

- Fluid type: The fluid media and the viscosity are important for seal efficiency and effectiveness.

- Hardware dimensions: The size of the seal will determine the size of the cylinder. This includes the rod and bore dimension, seal groove dimensions, gaps, cylinder’s overall length, surface finish specifications, and stroke length.

- Cylinder application: How the cylinder is used will impact how long the seals can last under certain operating conditions. This includes cylinder installation, environmental factors, and exposure to harsh conditions