Understanding the IP67 Rating for Industrial Networking Devices

Dust and water are the enemies of sensitive electronic components. Once inside a device enclosure, there is a possibility that over time it will corrode and deteriorate critical components, leading to overheating and eventual malfunction. Prevention relies on the enclosure's sealing effectiveness. So, how can we determine whether an enclosure suits the industrial environment in which it is deployed?

Enter the International Electrotechnical Commission (IEC). In 1975, the IEC created the Ingress Protection (IP) rating system to gauge a device enclosure's ability to keep out liquids and solids. Compared to ambiguous marketing terms like “waterproof” or “sealed,” the IP rating gives prospective buyers of industrial networking devices precise information regarding how well the enclosure will guard against the intrusion of external elements. Industrial and network security device manufacturers use IP ratings extensively. A certified IP Rating legitimizes an industrial network device and allows manufacturers to claim the level of protection their product delivers confidently. Manufacturers do not conduct their IP certification. Devices are tested by independent companies, such as UL, by performing a series of trials that replicate actual world conditions.

Understanding IP ratings can help you make informed decisions about where to deploy electronic devices. This article takes a close look at the IEC's IP rating system. Specifically, we explore the significance of the IP67 rating when choosing an industrial networking device for factories, outdoor installations, and remote sites exposed to environmental risks such as dust, humidity, and water. By thoroughly understanding the IP rating system, procurement specialists can effectively evaluate and compare different industrial networking devices, enabling them to choose the most suitable solutions for their particular operational requirements.

Industrial Networking Device Engineering

Industrial networking refers to the use of computer networks in industrial settings, such as manufacturing plants, oil refineries, and power generation facilities. These networks are designed to provide reliable and secure communication between devices and systems, enabling efficient and safe operation of industrial processes. Industrial computer networks typically involve wired and wireless network technologies, including Ethernet and Wi-Fi networks.

In industrial networking, network devices are critical in connecting networks and systems, managing data traffic, and ensuring network security. These network devices include industrial routers and industrial Ethernet switches. Industrial networks also rely on network protocols such as TCP/IP to enable communication between device networks, data packets and systems. By leveraging these network technologies, industrial networks can support various applications, from real-time monitoring and control to data analysis and remote access to digital data.

How IP Ratings Work

The IP rating system is a practical and universally consistent way to determine the level of protection an enclosure offers a network device against environmental factors like dust and water. While IP ratings don't measure network performance or security, they ensure that industrial networking devices, such as industrial switches and routers, are shielded from physical damage in harsh conditions. By preventing the ingress of dust, moisture, and other harmful elements, IP-rated enclosures help maintain the reliable operation of network devices, enabling them to manage data network traffic more effectively, even in challenging environments.

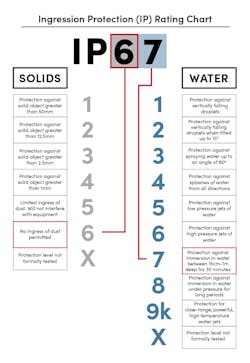

The IP code has two digits: the first (ranging from 0 to 6) represents the level of protection against solid objects, with 0 indicating no protection and 6 meaning complete protection against the ingress of dust. The second digit (ranging from 0 to 9K) denotes the enclosure's protection against moisture, from 0 (no protection) to 9K, which covers high-pressure hot water from various angles. Historically, a third digit was sometimes included to indicate the enclosure's resistance to mechanical impacts, but this has mostly been replaced by the IK rating system, which specifically measures impact resistance. If there is insufficient data to assign a specific protection level for either solids or liquids, an 'X' is used in place of a digit.

NEMA versus IP

The National Electrical Manufacturers Association (NEMA) establishes guidelines for producing electrical and medical imaging equipment. NEMA utilizes a standard rating system to define the environments and conditions suitable for installing multiple devices in multiple locations on the same network in an electrical enclosure.

Although both NEMA and IP ratings describe the level of environmental protection an enclosure will provide to networks, they use different variables, so there is no direct correlation. In addition to water and dust, NEMA considers protection against rain, ice, snow, and accidental contact with electrical parts while indicating whether the installation is in an indoor or outdoor location and whether the area is flammable or non-flammable. Protecting internal networks from environmental hazards using appropriate enclosures is crucial to safeguard sensitive data and ensure network devices' security features and reliability.

Being familiar with the NEMA and IP rating systems is essential. This knowledge will prepare you to house network devices inside a NEMA-rated enclosure on DIN rails when different networks are deployed in complex networks in harsh industrial or remote areas, such as an offshore drilling platform. With this competence, for example, you can ensure reliable network connectivity even in demanding conditions.

NEMA ratings consist of 10 different categories, each with data on its specific use:

- NEMA 1: Designed for general indoor use

- NEMA 2: Drip-proof for indoor applications

- NEMA 3: Protection against dust, rain, and ice (indoor and outdoor use)

- NEMA 3R: Protected from rain and sleet (outdoor use)

- NEMA 3S: Dust-tight, rain-tight, and sleet-tight (outdoor)

- NEMA 4: Water, dust, and sleet resistant for both indoor and outdoor use

- NEMA 4X: Water, dust, and sleet-resistant, and corrosion-protected

- NEMA 5: Indoor protection against dust and water dripping

- NEMA 6: Protects against hose-directed water, temporary submersion, and external ice formation

- NEMA 6P: Offers the same protection as NEMA 6 but with added resistance to prolonged submersion at a limited depth

- NEMA 12: Safeguards against dripping and dust for industrial applications indoors

- NEMA 12K: Protection against dust and dripping water, featuring knockouts for easy installation

- NEMA 13: Designed for indoor environments, providing a sealed enclosure that prevents the entry of dust and oil

IP Ratings in Industrial Switches

Industrial switches are subject to harsh environments, including dust, moisture, water immersion, chemical exposure, and other foreign objects. Another threat can come from cleaning systems with high-pressure streams that can jar connectors or lead to internal condensation.

With the correct IP classification, industrial switches ensure reliable and uninterrupted computer network connectivity in challenging industrial environments. These industrial Ethernet switches manage the same network segment and traffic in between different network segments to maintain optimal performance. But how do you determine an IP rating? Begin by evaluating the area where the switch or other network traffic or device will operate and identify potential environmental hazards. Standards and regulations should be consulted as well.

Let’s look at three different situations:

1. Food and beverage production (wet environment):

2. Wood and metal working, synthetics, battery manufacturing (dusty environments):

Process dust, another name for industrial dust, is generated during various manufacturing or production processes. Dust is produced, for instance, during cutting, drilling, grinding, or sawing. Another source of dust is the materials, powders, or ingredients used in the manufacturing process. An IP rating for solids of 5 to 6 is necessary to prevent dust from entering and building up in an enclosure. A high IP rating for liquids is likely unnecessary if the environment is non-hygienic, meaning less frequent washdowns.

3. Pharmaceutical plant (wet and dusty environment):

Manufacturing solid and powdered drugs, vitamins, or nutraceuticals can create large volumes of industrial dust, depending on the ingredients and processes. Pharmaceutical factories, like food and beverage plants, are subject to strict washdown procedures. Because hazardous levels of dust and water will threaten your network equipment and devices, a total IP rating of 55 - 68 should be considered.

Benefits of IP67 Rating

The IP67 rating is a standard for ingress protection that ensures a device can withstand exposure to dust and water. In industrial networking, IP67-rated connected devices are essential for ensuring reliable operation in harsh environments. The benefits of an IP67 rating include the following:

- Protection against dust and water ingress: Dust and water can damage network devices and disrupt network operation. IP67-rated devices are designed to prevent such ingress, ensuring the longevity and reliability of the equipment.

- Enhanced reliability and uptime: Devices with an IP67 rating are less likely to fail due to outdoor environmental factors, leading to improved network reliability and reduced downtime.

- Reduced maintenance costs: Since IP67-rated devices are more resilient to environmental damage, they typically would require less frequent replacement and maintenance in extreme conditions, resulting in cost savings.

- Improved safety: IP67-rated devices are designed to operate safely in hazardous and high moisture environments, reducing the risk of accidents and ensuring personnel safety.

Industrial networking applications can require an IP67-rated network device, such as an outdoor wireless access point. These devices are crucial for maintaining robust and reliable network connectivity in challenging conditions.

IP67 Rated Network Devices

At Antaira, meeting IP ratings is pivotal in shaping our product design and material decisions. It often requires increased engineering work to ensure tight seals against water and dust intrusion. Antaira IP67-rated devices operate at the network layer to ensure reliable communication in industrial environments. IP67 means these industrial Ethernet switches are:

- Completely protected from dust and airborne particles

- Can endure being submerged in up to one meter of water for up to 30 minutes

- Protected from contact with objects larger than 1 mm in diameter

Conclusion

Specifying the correct IP rating can significantly affect the performance and availability of industrial network devices. It could be the difference between your network running smoothly or experiencing costly production downtime.

About the Author

Henry Martel

Field Applications Engineer, Antaira Technologies

Henry Martel has over 10 years of IT experience along with skills in system administration, network administration, telecommunications, and infrastructure management. He has also been a part of management teams that oversaw the installation of new technologies on public works projects, hospitals, and major retail chains.