The Advanced Laser Marking Techniques Being Used in Automotive, Medical, and Electronics Markets

Laser marking has replaced traditional marking techniques in manufacturing because it's fast, requires no process consumables, and produces an excellent quality permanent or semi-permanent mark on a broad range of materials. Recent developments in laser sources and processing technologies have opened new, advanced techniques to further enhance manufacturing adaptability.

Marking Basics

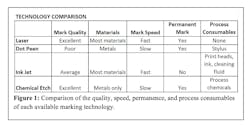

Marking is used for product identification, serialization, and aesthetics. A number of techniques have been developed to meet industrial needs in marking on a range of materials. Figure 1 provides an overview of four of the most common marking methods: Laser, dot peen, industrial inkjet printing, and electrochemical etching. Laser marking owes its recent popularity to its mark durability, flexibility in mark design, and minimal consumables.

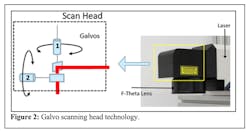

Laser marking works by focusing a laser beam onto a material surface; the interaction between the material and the laser light creates a permanent or semi-permanent mark. In most cases, a galvo scanning head is employed to rapidly move the beam over the surface (see Figure 2). Galvo scan heads employ two independent mirrors; the first controls the X-axis motion, and the second controls the Y-axis motion. The mirrors work in tandem to mark stationary parts at high speed.

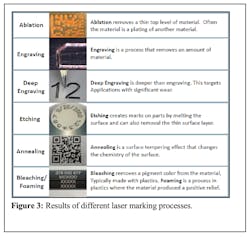

The types of marks that are possible using a laser and galvo scanning head include engraving, etching, color change, ablation, and more (see Figure 3).

Laser marking has a number of significant advantages including:

- Direct, non-contact processing

- Offers high contrast and fast processing times

- Chemical, water, and oil-free

- Flexible programming to produce text, barcodes, and pictures

- No retooling necessary to make different marks

- High legibility

- Long term durability

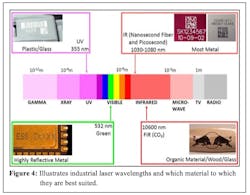

There are several types of common industrial marking laser sources. Because materials react to specific laser wavelengths differently, the material and desired mark type will inform correct laser selection. The four most common industrial lasers are CO2, IR (Fiber or Nd:YVO4), Green, and UV. Their wavelengths and typical markable materials are called out in Figure 4.

Advanced Laser Marking Applications

Manufacturers across multiple industries are adopting laser marking for a range of advanced applications. Following are three examples of how lasers successfully replaced other technologies to solve manufacturing challenges. Each case illustrates the challenge, the selection criteria used to develop the solution, the details and specifications of the laser selected to provide the successful outcome and other applications for which this solution might work.

Automotive Car Seat Frames – Durability and Traceability

In car seat manufacturing, aluminum frames are marked for traceability and identification with an adhesive label, but because the adhesive deteriorates as it ages, these labels often fall off with normal use (See Figure 5), thereby losing the traceability of the product.

The seat manufacturing company needed to change to a permanent marking solution.

The company’s requirement was to make a dark, legible-from-any-angle mark. The mark needed to be both human and machine-readable, and able to withstand the normal wear and tear endured over a car’s average 12-year lifespan. As a more advanced feature, they also wanted to connect the marking solution to their ERP/MRP/MES system for product traceability. The relatively low dollar value of the part meant that an equally low dollar value marking system needed to be considered.

Initially, the company tried direct ink jet printing onto the part but found it would rub off during lifecycle testing. So they switched to an infrared (IR) nanosecond fiber laser, which enabled them to achieve a dark and resilient mark. The dark mark was durable but lacked the contrast of the original black and white adhesive label which was machine-readable. By altering the laser beam and scan parameters, the same laser that made the dark mark was also used to make a white background for clarity and contrast. This increased both human and machine readability. The resulting, successful, black and white mark is shown in Figure 6. The barcode provided a mechanism to scan the part directly after the marking process and store it in the customer's ERP/MRP/MES system, providing them the means to fully trace the part from cradle to grave.

Medical Cannulas – Corrosion-Free, Black Marking

In medical device manufacturing, parts that come in direct contact with the body need to be sterile and devoid of crevasses where oxidation can form and contamination grows.

In this case study, a contract manufacturer for a medical device company was laser marking human-readable text and bands on 304 stainless steel cannulas with a nanosecond fiber laser. They were experiencing a high failure rate with marks not only oxidizing and corroding with extended use but also fading during the required autoclave processes.

In addition, they were marking on a range of parts—all with different diameters and wall thicknesses—where each part required unique recipe laser settings. This caused issues every time the customer added a new part.

The contract manufacturer needed to produce a clean mark—legible from any angle—that would resist oxidation and survive the wear and tear of repeated cleaning and passivation cycles. In addition, they desired a solution that could be easily applied to all of the different cannulae they manufactured.

The parts were relatively high-dollar items, and life safety critical. It was important to find the best solution, regardless of price.

While evaluating new technologies, they were introduced to a picosecond laser marker, which created fast, dark, high-quality marks that were readable and durable, resilient to multiple cleaning processes, and resisted corrosion after passivation.

The process of creating the mark using a picosecond laser is different than with a nanosecond laser. The nanosecond laser produces a black mark by an annealing process. Because annealing is heat-based, the amount of material present at the location of interaction results in varying degrees of heat build-up. The picosecond laser, on the other hand, creates a surface structure that traps light, resulting in a black mark, as shown in Figure 7. Since the micro-structuring process is not heat-based, the picosecond black marking process is not dependent on part thickness or different material alloy.

With the new marking capabilities of the picosecond laser marker, the contract manufacturer was able to look for other opportunities, increasing their ROI for this marking solution. Picosecond laser marking is ideal for other medical manufacturing applications, like labeling of pacemakers and other implants, banding for depth gauges, and branding on surgical tools like scalpels, tweezers, or scissors.

Electronic Micro Wires – Selective Ablation of Polymer Coatings

Electronic wires are usually coated with insulation to provide protection against environmental contamination, to help prevent short circuits, to provide a smooth, slippery surface (important for medical applications), and to reduce power leakage and increase electrical efficiency. That insulation, however, needs to be removed in order for the wires to make robust electrical contact and conduct current. Large gauge wires can be stripped mechanically, or with acid. As the gauge becomes smaller, however, it becomes impractical to quickly and cleanly strip them, one by one, by hand. Acid is also generally not preferred for safety reasons. Using a flame—yes, sometimes companies use fire—can compromise wire strength and leave a melted residue.

In this case study, a medical device manufacturer needed to cleanly strip not only the ends of a small gauge wire but also some selected locations in the middle of the wire length. The desired result was a smooth, residue-free surface for easy attachment to the terminals.

Neither a CO2 nor an IR laser was able to cleanly remove the coating without leaving residue and imparting too much heat into the copper wire, and mechanical stripping led to a high defect rate.

A UV diode-pumped solid-state laser was selected as a potential solution. The short wavelength was easily absorbed into the coating without putting a lot of heat into the metal itself. For this particular wire and coating combination, two passes of the laser were needed in order to completely remove the insulation. The resultant stripped wire is shown in Figure 8. Once stripped, the manufacturer was able to make the connections needed to complete the build of their parts.

Although wire stripping is not a traditional marking technique, it demonstrates the flexibility of the technology. The UV laser can also be used to mark a range of plastics and glass. Applications include labeling of medical casings and coverings for instruments and pill bottles; electronics identification markings, like LCD panels or cell phone covers; and electronic component identification.

Summary of Laser Type and Features

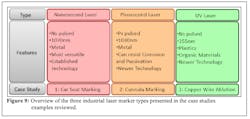

This article presented three case studies, each one solved using a different laser source: a nanosecond fiber laser, a picosecond laser, and a UV laser (see Figure 9). The unique properties of each of these lasers solved an existing manufacturing issue while improving durability and production throughput.

In addition, as demonstrated in the first case, laser marks can also be used for traceability. In summary, the development of new lasers and new techniques are making inroads for advanced manufacturing. New ideas of how to use these lasers will continue to innovate the next products—we are excited to see what’s next!

Mark Boyle is a Senior Manager of Product Engineering and Applications at AMADA WELD TECH. Jessica Ashkinos is a Laser and System Product Engineer at AMADA WELD TECH.