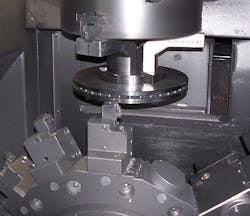

The manufacturing process for brake discs at Otto Zimmermann involves several essential steps: The cast blank is turned on a lathe and the hole pattern is drilled in the hub of the brake disc. The brake discs are then balanced and a special heat-resistant aluminum coating is applied for protection against corrosion.

The differences in manufactured brake discs are not always easy to spot, making it all the more important to know and understand the criteria that define a quality product.

In the field, Zimmermann staff repeatedly encounters brake discs from other brands that have been manufactured with less than perfect precision and likely fewer process steps than is technically required. For example, some brake discs turn out to be unbalanced. According to ECE (Elastic Charging Engine) specifications, balancing measures must be equivalent to those used for the OE (original equipment) part.

To the untrained eye, it's not immediately obvious whether or not brake discs have been balanced. Looking at the milled groove can help determine if the brake disc is unbalanced. To rectify an unbalanced disc, the material will be shaved off very precisely (to within 0.5 g (0.005 kg)). Other balancing methods, such as adding weight by inserting wire clips into the ventilation channels, have become obsolete over the decades and are rarely seen in today's aftermarket. However, there are now manufacturers who skip the crucial step of balancing altogether.

Due to the casting process, ventilated brake discs feature areas that cannot be machined or turned—for example inside the ventilation channels. To compensate for these inherent imbalances, a precise balancing operation is indispensable.

What Happens if an Imbalanced Brake Disc Is Installed?

An increased level of imbalance creates a radial runout that can result in vibrations in the steering wheel and across the entire vehicle. The intensity of these vibrations varies depending on the vehicle speed and affects wheel traction as well as driving comfort and ultimately safety.

In the long run, damage to wheel bearings or the entire wheel suspension is likely. In the case of imbalanced brake discs for the front axle, the control arms, pull bars, push bars, and strut bearings are particularly affected.

To avoid these issues following the installation of new brake discs, it's important to make sure, before installation, that only quality brake discs are used and not products that only seem good at first glance. If you happen to have unbalanced brake discs, you can take them to a service provider who can shave them down and balance them out for you.

For more than six decades, Otto Zimmermann GmbH has been developing, producing, and distributing sophisticated automotive components for car manufacturers and the independent aftermarket. In addition to standard spare parts, the company also develops sports and premium brake discs for the requirements of motorsports and tuning. Otto Zimmermann is a TecDoc "Premium Data Supplier".