When It Comes To Welding Aluminum, Laser Provide the Best Results

Manufacturers in the battery, aerospace, and communications industries are tasked with manufacturing reliable, hermetically sealed packages to protect the sensitive electronics contained within. Packages should be lightweight, thermally and electrically conductive, non-magnetic, and possess a glossy, attractive finish.

To achieve this, manufacturers often turn to aluminum. But aluminum is notoriously difficult to weld, posing manufacturing challenges.

Laser welding with a high-power, single-mode fiber or Nd:YAG laser is the best option due to its speed and low heat affected zone. Ideally, parts should be designed with a recessed butt joint for accessibility, repeatability, and automation. Consider welding in an inert environment to keep moisture, oxygen, and other contaminants outside the package.

Why Aluminum?

Aluminum—whether used for prismatic battery cans, supercapacitors or microelectronic devices including RF and microwave housings—is commonly selected due to its relatively low cost, thermal and electrical conductivity, attractive finish, lightweight, and limited susceptibility to corrosion. But the very qualities that make aluminum desirable, can also make it difficult to work with.

The following properties pose challenges when welding aluminum:

- Low melting point

- High thermal conductivity

- Susceptibility to impurities in its molten state

- Naturally occurring oxide layer

The greatest of these challenges is aluminum’s low melting point (660°C/1,220°F) which results in a very small welding window and, in its molten state, susceptibility to impurities that result in weak, porous welds.

Adding to the challenge is aluminum’s great affinity for oxygen, and its tough, naturally occurring oxide layer, which possesses a significantly higher melting point (2,072°C/3,762°F). Without additional processing, very high energy is required to burn off this layer, but that same energy in contact with the lower melting point aluminum base causes metal expulsion/spatter. In order to overcome this challenge, the oxide layer must be cleaned from the metal before welding and processed before it reforms.

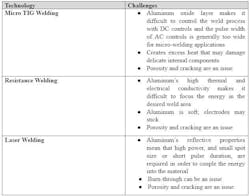

Welding Aluminum: Comparing Technologies

Manufacturers have a number of technology choices for welding aluminum, each with its own set of challenges. Let’s look at a comparison of the three most commonly used technologies:

While all three technologies present challenges, laser welding is the best choice for welding aluminum packages because it generates the smallest heat-affected zone, protecting the sensitive contents of the package. Although there are still some welding challenges, these have known solutions.

Tips and Tricks for Successful Laser Welding of Aluminum:

- Because it's more prone to impurities which can lead to weak, porous welds, aluminum must be thoroughly cleaned to remove oil, grease, fingerprints, and other surface contaminants.

- Remove surface oxide using a brush, acid or laser.

- Assemble the parts quickly to avoid further contamination.

- Keep dry and at room temperature. If not welded within a few days, repeat the cleaning process.

- Select aluminum alloys that are known weldable combinations.

Laser Welding Aluminum Solutions

Selection of the best laser solution for your specific aluminum package welding application is dependent on many factors including part design, factory floor space, budget, and more. Laser engine options include Pulsed Nd:YAG, CW fiber laser or QCW fiber paired with a focus head to deliver the energy to the part.

Pulsed Nd:YAG

The most traditional laser source for aluminum welding and is still preferred for more complex geometrical welds, where stage motion limits speed in corner areas. Its larger spot sizes help accommodate for fit-up tolerances providing a fairly robust weld for production. This laser choice is most commonly configured with a fixed focus head.

CW Fiber Lasers

These are becoming more popular due to low consumable nature and faster weld speeds. The limiting factor is its small beam diameter. This laser is typically mated with either a wobble head or a galvo beam delivery system that can oscillate the beam, increasing the melt pool and overcoming component manufacturing tolerances (the gap between parts). This laser is best for welding from the top of the package where the geometry is 1D or 2D.

QCW Fiber Lasers

Provide a solution somewhere between Pulsed Nd:YAG and CW fiber lasers. In pulsed mode, these lasers behave similarly to the Pulsed Nd:YAG laser. Pulsing can be controlled to limit heat input to the part. However, these typically have small spot sizes which can make it challenging to bridge gaps between parts, thus component manufacturing tolerances need to be tighter. For pulsed mode, it's common to combine with a fixed focus head.

One difference between pulsed Nd:YAG and QCW is that the QCW can pulse at much higher repetition rates when the process requires it. This can reduce manufacturing time.

Package Design for Successful Laser Welding

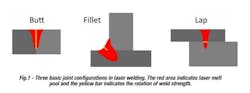

The three basic joint types commonly used for laser welding are butt, fillet, and lap. We recommend butt welding configuration, if possible, to achieve the very best hermeticity and the greatest strength per watt of laser power as the laser penetrates directly down the interface line between the two parts. The figure below shows weld penetration for the three basic weld geometries. The strength of the weld is found along the yellow line.

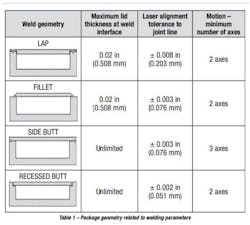

Package Geometry Related to Welding Parameters

The table below shows four common package design geometries. Of the four, the recessed butt joint weld is preferred for welding aluminum packages because of the following advantages:

- Easy, repeatable positioning of the lid.

- Beam access from the top, limiting the number of degrees of motion.

- Easier to automate, with the potential for multiple-up configuration.

Potential risk for weld spatter onto the package and the draw process to form the packages can create tolerance issues. These can be overcome by proper laser settings in combination with a visual motion system to identify the seam and make a weld along that axis. Recessed butt welds require complex part machining with base and lid fit tolerance of fewer than 0.002 inches (0.051 millimeters). It requires 2 axes of motion and good joint line alignment.

The second best choice is a side butt weld. A simple, flat lid of any thickness can be used. Creating a strong joint requires at least 3-axes of motion and good joint line positioning. The laser beam is aimed horizontally at the parts and gravity is utilized to aid with part tooling and load/unload. Package design, however, makes the tool path more challenging.

Though aluminum is the material of choice for many electronic package applications, it is notoriously difficult to work with. Manufacturers can achieve the best results—strong welds with excellent hermeticity—using laser welding in a butt weld configuration.