Distributing water on a large scale has been a challenge that the world has tackled for decades. It is a particular challenge in high-rise buildings, and with a trend for designers to build up in urban areas, rather than out, it is a challenge that has become a new focus for design engineers.

Occupants of these buildings – office and factory workers, apartment and condo residents, are all very sensitive to failures of the water distribution system. People get upset if their hot water for showers and baths are intermittent or totally run out because people on other floors use up the available allocation of heated water.

What happens when hot water does not immediately start flowing? People let the water run until the flow heats up – potentially wasting a great deal of water as well as the energy required to pump and distribute the water.

In addition, consistent water pressure is a must for correct operations of appliances like dishwashers and laundry machines as well as for industrial and manufacturing machinery.

The challenge to improve the mechanics of building water distribution systems is driven by two fundamental needs: firstly, the need to increase efficiency, and in doing so, decrease water wastage; and secondly, to improve the reliability of the installed systems, thereby reducing the ongoing cost of maintenance and repair.

Old-world thinking

Old technology pumps in large industrial water systems typically use pressure switches calibrated to switch the pump on if the water pressure falls to below a specific point (say, below 50 psi) and off if the pressure exceeds a given parameter (for example, 70 psi). This operation is fine up to a point, but it essentially means that the pump is either working at full speed or not at all, and these surges in demand placed upon a mechanical system may lead to problems with reliability and repair. Although undoubtedly rugged and reliable, the industrial systems of old also tended to be expensive and inefficient.

Alternative solutions

Therefore, pump and water system designers have looked for alternative solutions. First amongst them is the new Variable Speed Pumps (VSP).

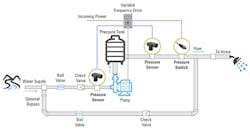

VSPs use a Variable Frequency Drive (VFD) or Variable Speed Drive (VSD) to continuously optimize the pump speed and power consumption while maintaining constant outlet pressure of the pump. In such scenarios, pressure sensors are essential. A pressure sensor converts the outlet pressure to an electrical signal which the VFD uses to adjust the pump’s speed and is either included as an integral part of the pump design or mounted externally as part of a total solution.

Similarly, in many cases, a high cut-out pressure switch is mounted to prevent the pump from outputting extreme pressure. An additional pressure sensor can also be mounted on the inlet of the pump to monitor efficiency.

Benefits of Variable Speed Pumps (VSP)

The benefits of pressure sensors in modern-day Variable Speed Pump design can be categorized into three key areas: efficiency, reliability and the user experience:

- Efficiency - Pumps that utilize VSDs in conjunction with pressure sensors to maintain constant pressure output are proven to be more efficient. Indeed, in tests, they are proven to be up to 30% more efficient than ‘traditional’ technologies (Hydraulic Institute, Europump, & U.S. Department of Energy, 2004)

- Reliability - VSPs often run at lower speeds and do not run on an outdated ‘stop/start’ cycle, therefore there is less stress on the pump which results in greater reliability, a longer life cycle, and less downtime. This, in turn, means a lower cost of maintenance.

- User Experience – The efficiency and reliability of a VSP ultimately translate into an improved customer experience. Even in the more challenging environments, such as high-rise buildings, a constant, reliable water pressure can be maintained. Beyond the undoubted benefit of more reliable water supply, customers are also able to easily modify the pressure supply (depending on load and preference). The digital nature of the technology also allows for greater connectivity with the Internet of Things (IoT), effectively making the pump an intelligent device providing key data that can be acted upon in the event that a problem is identified, such as a burst pipe or leak, or to determine water usage. By using IoT connectivity, building managers can remotely monitor and regulate water use, as well as respond in an emergency by either turning the water systems off to reduce spillage or by allocating the highest water press to combating emergencies, such as fighting fires on the higher levels of a building.

Use and application of Variable Speed Pumps

Traditionally, VSPs have been used in larger, commercial and/or industrial applications, given the previously high costs involved. As costs have come down, and designs improved (notably the cost and size of electronics in the VFD and VSD), VSPs have become affordable in more mainstream, residential applications.

This growth has been driven not simply by falling costs but, more importantly, by rising demand. Increasing urbanization on a global scale, often combined with a less than consistent municipal water supply, and power supply mandates, means that the effective delivery of water is a very real challenge. This, in turn, has prompted the sensor manufacturers to innovate.

It is notoriously difficult to maintain constant water pressure to every story of a high-rise building, but this is again where the new generation of pumps and sensors come into their own, replacing the inefficient and inconsistent ‘traditional’ approach to water provision via a rooftop water reservoir.

Sensors can detect variations in water pressure to determine when the pump needs to work a little harder to maintain constant pressure and when it can relieve the pressure, but without the extremes of being either fully ‘off’ or fully ‘on’. Pumps work more efficiently if they are run at a constant rate; they are also less prone to failure, with all of the associated costs of ongoing repair and maintenance.

Pressure sensor innovation

Sensata has a range of sensors for use in industrial pumps where components require rugged, industrial housings. For example, its 60/70CP range pressure sensors are proven for use in other industries that require the reliable pumping of liquids, such as oil, and with a very high degree of reliability (10 million cycle life-span). They are also robust enough to withstand potentially damaging phenomenon such as pressure spikes and hydraulic shock.

As well as the proven 60/70CP sensors, Sensata has recently launched a cost-efficient pressure sensor family (116CP/126CP), for smaller residential booster pumps. The patented 116CP/126CP sensor design is derived from highly reliable and proven automotive grade pressure sensing technology. The sensors’ innovative plastic housing has options for use in drinking water applications and makes them ideal for residential and other lower-cost pump applications.

The pressure sensor converts the pressure signal into an electronic value which the pump VFP uses to control or maintain the output pressure. The sensor measurement pressure value is usually presented on the pump’s display, and in some cases, customers are able to view and monitor pressures via an application on their smartphone or tablet. In addition, a notification can alert users of irregularities and assist in preventative maintenance.

The world’s water systems are in desperate need of improvement – especially as the world’s water resources continue to shrink. Many have predicted, with the advent of global warming and climate change – that access to clean, potable water will be the most critical element of life in the next century. Anything we can do to improve overall water distribution efficiency and reduce waste will be of benefit as the world’s population continues to grow and migrate in response to changing climates and rising ocean levels.

Companies like Sensata, who are developing and implementing new technology water pumps and pressure sensors, will play a crucial role in the design of residential and commercial solutions that drive system efficiency and reliability and help to reduce waste while improving the user experience.