How believably immersive has AR/VR become? Enough that I found myself almost running directly into a wall during a laser space battle at Altered Reality in Indianapolis. After I had regained my balance, I abruptly ended the hyper-realistic simulation and opted for another scenario called "Job Simulator." Far better for a beginner such as myself, this particular game showed the real value of AR/VR: employee training modules.

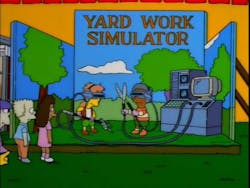

While the Laser Space Death 3000 (I’m taking creative liberty with the name based on my personal sentiments) was a 100 on the entertainment scale, the practical application was a resounding zero. "Job Simulator," while cartoonish, was far more practical. The premise is simple: pick a traditional job such as office worker, short order cook, etc. and proceed to complete a series of tasks associated with that position. I was able to stamp resumes, answer emails, cook a full order breakfast, and even throw paper airplanes in my downtime.

This simulation is just one example of how the AR/VR world is adapting to fit into a niche, self-curated market. Let’s use the medical field as an example:

An X-ray machine costs hundreds of thousands of dollars. When you are training a new tech to operate the machinery, not only are you worried they may damage the machine, you are actively diminishing the number of X-ray machines available to paying "customers." With the right AR/VR simulation, you could train all new techs, simultaneously, without any physical machine present.

VisionThree is a company in Indianapolis that has made a business around this very idea. They work with organizations to create custom virtual reality training scenarios, allowing employees to learn in a risk free, low stress environment without compromising the quality of their training. New employees can familiarize themselves with pieces of equipment, building layouts, and more with no risk of their early failure impacting your bottom line. In one use case, VisionThree says VR was used to train Dow facility employees on locating signs of pest infestation and what actions to take. In another, Rolls Royce used the tech to create an immersive understanding of their RR300 helicopter turboshaft power plant.

Google recently announced their latest VR project that allows students to perform lab experiments minus the lab. No more emergency eye-wash stations, no more acid burning through tables. Because you are no longer confined to the realm of the possible, the simulation includes out of this world features that allow you to pull apart 3D models of molecules, run tests on virtual animals, manipulate DNA strands, even dive inside of cellular components for a close up view. All of these actions can be performed virtually, with no cost of materials or risk of hazardous conditions.

The future of AR/VR is affordable, manageable, and scalable training solutions for a variety of industries. Everyone loves a good space laser battle, but that’s not where the true value of this technology is found.

John McDonald is the CEO for ClearObject, an IoT systems integrator that designs, develops, deploys, and manages innovative connected solutions and digital data products.