Direct-to-Package Printing: The Sustainable Alternative to Shipping Labels

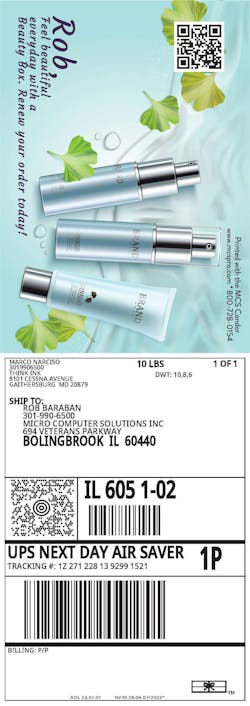

Businesses relying heavily on corrugated boxes or bags as secondary packaging, including e-commerce sellers, retailers, and manufacturing companies, are actively seeking alternatives to standard adhesive shipping labels. Printed adhesive labels are primarily used for variable data such as addresses, tracking codes, product identification, and instructions for use. Labels can also include logos, brand messaging, and other promotional elements.

However, labels have significant disadvantages, including being an enormous source of environmental waste. Large volumes of paper, films, adhesives, printing plates, solvents, and chemicals are typically left over as byproducts of the label production process. Most adhesive labels are not recyclable and can contaminate the box or bag, making it no longer recyclable. Plus, there's an added cost associated with label stock and printing.

To mitigate these environmental impacts, shippers and e-commerce retailers are increasingly exploring alternative solutions that are more sustainable and eco-friendly. This includes eliminating the need for a traditional adhesive label by printing directly on secondary packaging using high-speed inkjet systems.

The technology, already used in the mail manufacturing industry to produce personalized mass mailings at high volumes, eliminates the primary barrier to direct printing—namely the ability to print in full color with variable information at extremely high speeds.

A Blank Canvas for Promotion

Secondary packaging plays a significant role in marketing and branding strategies. In addition to safeguarding primary packaging, it provides an opportunity for companies to showcase their brand identity, logos, slogans, and promotional messages to attract the attention of potential customers. By carefully considering the secondary packaging design and shipping methods, e-commerce retailers and shippers can differentiate themselves from their competitors and increase the likelihood of customers choosing their products.

This applies, of course, to the traditional adhesive labels used on corrugated boxes and bags.

However, given the volume of packages shipped, there is an industry-wide mandate to reduce the environmental impact along the entire chain. As sustainability becomes more critical, corporate leaders like Amazon are looking for ways to significantly improve their mail and packaging efficiency while reducing their environmental footprint. This includes opting for electric delivery vehicles, decreasing single-use plastic, and moving to 100% recyclable paper and cardboard packaging.

According to an article from Packaging World, Amazon is investing in CMC Machinery, a company with technology that makes custom-sized boxes that eliminate the need for single-use plastic packaging. CMC specializes in constructing customized packaging solutions that build customized boxes based on the size and type of item to reduce the amount of air (unused space) in the pre-made boxes.

"Amazon expects that the technology could reduce the cubic volume for each box by 24% on average and reduce the use of approximately 1 billion plastic air pillows by the end of 2022," according to the article.

The equipment, called the CartonWrap 1000, can pack boxes much faster than a human packer, processing up to 700 orders an hour. In addition to helping Amazon get its packages ready faster, CMC was able to significantly reduce the number of brown boxes used in packaging orders, resulting in a reduction of approximately 70 to 80%.

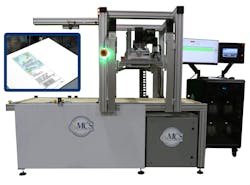

This concept spurred MCS Inc., a company that designs, manufactures, sells, and supports high-speed industrial inkjet imaging systems for the mail manufacturing industry, to conduct tests on packaging equipment at its facility to explore the idea of incorporating advertising messaging in process color directly on the packaging.

In the high-stakes world of mass mail manufacturing, the cost of printing errors can be significant. Not only is the mail manufactured at extremely high speeds, but the range of high-value personalization features used to increase response rates makes matching variable printed materials, envelopes, and attached cards without errors increasingly important. After all, the internal contents of an addressed envelope may contain sensitive financial or health information and should not get into the wrong hands.

A leading supplier of high-speed mail manufacturing equipment since 1989, MCS’ inkjet and tracking products are designed and manufactured in the USA. With thousands of systems installed in the mailing and marketing industries across North America and the world, MCS equipment has been used for many mission-critical mailings including two U.S. Censuses and many vote-by-mail elections.

"We are already getting quite a few inquiries from logistics and fulfillment companies asking about images that can be printed directly on boxes and bags," says David Loos of MCS.

Direct Printing of Corrugated Board

Corrugated board is produced by combining various papers together in the form of paper layers. These layers are called liners and fluting (the fluting being formed to create a specific profile). The liners can be pre-printed with standard messaging before it is glued to the medium. This is a cost-effective method for high-volume production.

After the corrugated board is converted to boxes, "High-speed, direct-to-packaging inkjet printers could then be used in defined locations on the box to deliver customized promotional messages such as a special offer, or an announcement about a new store opening in a region," explains Loos.

Direct Printing of Custom Bags

Loos says that MCS was approached last year for a solution that would print trackable variable barcodes directly on shipping bags. Many larger bag suppliers invest in high-tech manufacturing equipment to offer cutting-edge bag solutions, including modern bag designs in many shapes, variations, and types of substrates. The bags are used by e-commerce sites for shipping and online retailers that offer home delivery services.

For high-speed printing, roll-feed flexographic printers are used. The paper rolls are then cut into sheets at approximately the same speed. The concern was whether direct-to-bag printing systems could keep up. The average inkjet printer operates at a speed of 105 to 500 feet (45 to 150 meters) per minute. However, MCS has printers that can reach speeds of up to 1,000 feet (300 meters) per minute.

"We print on a wide web at very high speeds and there are very few [direct print inkjet] machines that can run at a thousand feet per minute and print the high-quality tracking codes at that speed," says Loos.

Although the bag is printed on a flexographic printer, space is available on the press to add an inkjet printer for direct printing of tracking codes and “just about anything else you can think of," according to Loos.

"Instead of a label going on that affects the cost and affects the recyclability of the product, we can now digitally print that unique code directly on the bag using the MCS printer," says Loos. "We can print anything the customer wants, including notifications about store openings in their area, special offers, links to sales or other sites, or other promotional messages."

MCS Hayabusa Inkjet Features:

- High speed of up to 1,000 ft/min (300 m/min)

- Low maintenance

- Industry-leading darkest black

- Workflow-supports PDF and IJPDS

- Stock includes porous, coated, aqueous, and up to 12 pt, including label stock

- Up to 130,000 letters/h

- Up to 240,000 self mailers/h

The equipment used is one of the fastest inkjet printers in the industry, the MCS Hayabusa Inkjet, which delivers print widths from 4.25 to 34 inches. The inkjet printer comes with MCS' Raptor software, which manages the custom messaging and variable data seamlessly with any printing solution required.

MCS offers other direct-to-packaging alternatives at different speeds and price points. This includes inkjets that can apply process color and monochrome printing horizontally or vertically.

According to Loos, the speed of the printing and the elimination of the need for a label are the primary benefits of such systems.

"Label applicators are not nearly fast enough to keep up with a flexographic printer. One printer may serve six or seven bag machines, and that would require six or seven label applicators," says Loos. "With direct printing, no applicators are required. This approach also reduces the costs of the bags."

Loos believes that direct printing to bags or boxes will have many applications in the future now that the primary barrier of speed is no longer an issue.

"I think there is a very good potential to offer printing directly packaging, not just for QR or barcodes, but for promotional statements, says Loos. "The e-commerce retailer or home delivery service can choose exactly how they want to use it."

For more information on MCS and its inkjet printing solutions, visit mcspro.com, call (800) 728-0154, or email [email protected].

About the Author

Jeff Elliot

Jeff Elliott is a Torrance, Calif.-based technical writer. He has researched and written about industrial technologies and issues for the past 15 years.