IMTS 2024: Canon and OSARO Collaborate on AI Robotic Bagging Technology for Warehouses

Canon U.S.A., Inc., a digital imaging solutions provider, will demo a new customer solution that integrates Canon technology.

OSARO Inc., a San Francisco-based Canon U.S.A. customer that provides AI-based robotic perception and picking solutions, will display the OSARO Robotic Bagging System which uses Canon's optical-encoder-based, durable, and low-cost force-torque sensor, at the International Manufacturing Technology Show (IMTS 2024). The solution will be on display at Canon's booth #134040 in the East Hall.

The sensor can measure the magnitude and direction of load along three axes and rotational forces. When attached to a robotic arm, a force sensor helps the arm sense the strength needed to handle objects.

Canon's force sensors, featuring a simple structure due to their advanced optical encoders, are durable, thin, lightweight, precise, and fully digital providing a low-noise effect. They can be installed on robotic arms for various tasks, aiding with automation for areas that are still reliant on manual work. The sensors are also less prone to damage compared to older analog methods due to it being a non-contact structure.

The force torque sensor, measuring just three-quarters of an inch (in thickness) and weighing .55 lb., contains Canon's proprietary optical encoder technology. A digital mechanism works to provide high precision levels, and the Canon Force Torque Sensor Application Software allows users to connect their sensor to a personal computer without any need for coding while testing.

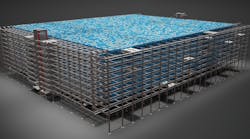

OSARO's Robotic Bagging System aims to transform order fulfillment by automating SKU bagging with advanced pick-and-place software that integrates with leading packaging equipment. This system can reduce overhead and mitigate labor shortages while meeting the customer's throughput requirements.

Powered by OSARO's AI and machine-learning algorithms, OSARO SightWorks delivers flexibility by automatically adding thousands of new SKUs without downtime.

With dynamic object detection and the ability to adapt to changing inventory in real time, SightWorks ensures accurate, efficient, and versatile order processing.