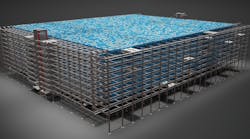

The Flexible Pallet Tower (FPT) automation solution is a compact pallet automation solution for a single CNC milling machine with 11.8 to 24.8 in. (300 to 630 mm) pallets. FPT integrates with any machine with a wide library of ready-made machine tool interfaces and multiplies the machine tool utilization up by cutting down setup times and enabling lights-out manufacturing. The plug-and-play automation system also shortens the lead times and allows for higher part mix with smaller unit costs, no matter the production batch sizes.

Compared to other similar systems in the market, FPT is compatible with any machine tool brand, and it integrates with milling machines whether or not they have automatic pallet changers. In addition, the system footprint is extremely compact: FPT-500 for 11.8 to 19.7 in. (300 to 500 mm) pallets requires only 100 square feet, and FPT-1000 for 19.7 to 24.8 in. (500 to 630 mm) pallets requires 175 square feet. Instead of having a fixed storage, like most of the comparable units, FPT can work with different load heights and pallet sizes with a configurable pallet storage that can store up to 24 pallets in two to four levels.

FPT is controlled by the Fastems Manufacturing Management Software (MMS). MMS offers a single-view user interface with drag-and-drop production scheduling and allows bringing new workpieces into the system in under 60 seconds. The system automatically tracks and reports the key performance indicators in real time.

- Plug-and-play automation system

- FPT-500 for 11.8 to 19.7 in. (300 to 500 mm) pallets requires only 100 square feet

- FPT-1000 for 19.7 to 24.8 in. (500 to 630 mm) pallets requires 175 square feet

- FPT is controlled by the Fastems Manufacturing Management Software