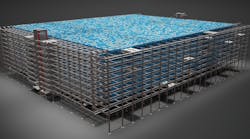

SimpliFil Syringe Filling & Assembly System

Suitable for small to medium batches, the SimpliFil Syringe Filling & Assembly System effectively increases automation and reduces labor. The pre-assembled syringes are loaded manually by an operator onto the walking beam, which will index the syringes to the first station where the plungers will automatically be positioned for filling. Filling up to 36 syringes per minute, the system smoothly handles syringes with tips outfitted for press-on caps and luer caps, as well as various safety caps recently incorporated for oral syringes.

The syringes can be filled by either direct draw from a reservoir bag, a peristaltic pump, or a piston pump (316L stainless steel, or ceramic), based on product compatibility and customer preference. The syringes will be filled using TipFil technology, allowing filling of the syringes through the "tip" instead of the "tail."

After being filled, the syringes will be moved to the next station where the caps will be place automatically on the tip (nozzle) of the syringe using a stainless steel vibratory bowl feeder, track, and placement mechanism. The caps will then be torqued using a servo driven torquer.

After being capped, the syringes are inspected for cap placement and missing fill. The syringes that do not pass will be ejected into a reject bin. The syringes that pass will exit the walking beam and be dropped in a bin.

The system can be fully customized to specific requirements, including aseptic processing.???

- TurboFil's walking beam conveyor

- PLC machine controller (Allen Bradley)

- Stainless steel vibratory bowl feeders

- Plunger pullback via servo controlled draw

- Back check valve for air purge

- Suck back nozzle design for drip free operation

- Pneumatically driven syringe support for securing the syringes during the fill cycle

- Top syringe support

- Liquid filling accuracy +/- 0.5%