Energy-Reducing Pallet Motor Rollers

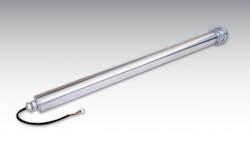

PULSEROLLER pallet handling motorized drive rollers (MDR) safely and effortlessly move pallets up to 70-in. wide and weighing up to 2,700 lb. on a conveyor line. The low voltage pallet rollers are designed to replace any AC gear motor solution by simply removing the motor/gearbox unit and dropping in the heavy-duty pallet roller with sprockets directly inline with the other conveyor rollers. Depending on the application, energy savings can be as high as 60% when compared to alternatives, while providing a safer and more energy-efficient conveying solution.

The pallet roller is driven by a powerful 24VDC motor engine installed inside the tube and coupled to an industrial hardened multi-stage planetary gearbox assembly that easily conveys loads of 2,700 lb. Conveying heavier loads is possible by adding another motor inside the tube creating a dual-motor roller, or by simply doubling the number of pallet motor rollers in each zone.

Using PULSEROLLER’s industry-standard ConveyLinx control card, PULSEROLLER pallet rollers can reach speeds up to 25 m/min with up to 49.3 N-m (436 in-lb.) of torque. This enables a user to move heavier loads with less energy (current) while maintaining the required speed.

With a choice of EthernetIP, Modbus TCP, ProfiNet, or EtherCat connectivity, the networked ConveyLinx cards facilitate virtually any control strategy at a very attractive price. Simple ZPA, transportation, indexing loads, minimum pressure, sortation, pick & pass are all strategies easily implemented by using the built-in intelligence of ConveyLinx or by writing your own program directly. Users have complete control and monitoring capabilities of every motor in your system over a single Ethernet network.

PULSEROLLER pallet handling motor rollers are available in standard 2.25, 2 3/8, and 2.5-in. diameters with many optional attachments including sprockets, poly-vee, keyway, timing pulley, and more.

- Safe and efficient 24VDC power

- Reliable gearbox design that's heat-treated and reinforced steel

- Highly efficient, powerful motor improves life expectancy

- Moves up to 2,700 lb.

- 9-pin JST connector for simple and cost-effective Installation

- IP54 and IP66 wash down rated

- Senergy engine inside!

- Compact design

- Dual geared pallet - double the torque

- 2.25, 2 3/8, and 2.5 in.

Conformance

CE, RoHS, IP54

Certifications

ETL Listed to UL 1004-1 & UL 1004-6

Tube Material Options

Zinc Plated Mild Steel, Stainless (SUS304)

Available Roller Diameters

60.5 mm (2.38 in.), 63.5 mm (2.5 in.)

Min. Tube Length

450 mm

Max. Tube Length

1,800 mm

Cable Length

600 mm (SENERGY) / 1,000 mm (SENERGY-Ai)

Motor Connection

9-Pin JST (SENERGY) / 4-Pin M8 (SENERGY-Ai)

Duty Cycle

1.0 sec ON / 1.0 sec OFF minimum

Operation

Continuous at rated load/current without overheating

Boost-8 Mode Recommended

Voltage

DC24V

Nominal Output

50W

Rated Current

3.5A (Boost and Boost-8)

Starting Current

5.0A (Boost), 8.0A (Boost-8)

Ambient Temperature

-10 ~ 40°C (14 ~ 104°F) (No condensation)

Ambient Humidity

10 ~ 90% RH (No condensation)