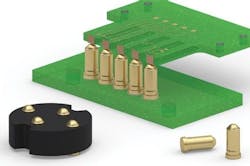

Spring-Loaded Contacts

The unique Omniball spring-loaded contact (patent pending) features a rolling ball interface, enabling mating components to engage in lateral, rotational, and angular alignments while providing optimal electrical, mechanical, and structural reliability.

The Omniball contact (P/N: 0945-0-15-20-09-14-11-0) is a spring-loaded pin in which the traditional plunger has been replaced by a gold-plated ball. It is designed to simplify and improve the connections made between components that are mated together in a sliding or rotational motion rather than in an axial or vertical orientation. When engaged, the ball compresses and rolls, allowing the mating surfaces to make contact and then easily slide parallel to each other while spring force acts to ensure consistent electrical contact is maintained. This rolling action alleviates the concerns of connector damage such as binding, premature wearing, and structural failure that may occur when using traditional plunger style spring pins in these types of applications.

Features of the Omniball contact include .030” (.762 mm) maximum stroke; overall height of .266” (6.76 mm); gold plating on all components; surface mount termination. These spring-loaded pins are durable, they have been tested to 1,000,000 compression and rolling cycles at a half stroke while still meeting specifications for contact resistance of 20 mili-ohms max., current rating of 3.5 amps and spring force of 55 grams at mid-stroke (.015”, .381 mm).

Omniball® contacts are an excellent choice for any application that involves sliding or rotating connections, such as: “twist & lock” cable connectors; smart lens camera connectors; rugged and IP rated connectors including quarter turn and threaded; as well as docking stations, quick connects and blind mating applications. These unique contacts are available as individual pins and in a 4-pin circular connector which is offered in tubes (P/N: 945-22-204-30-360101) and in tape & reel packaging (P/N: 945-22-204-30-360191). The 4-pin connector is especially well suited for round cable connector applications.