What is Plug & Inspect?

By Yonatan Hyatt, CTO, Inspekto

Traditionally, machine vision solutions are developed and installed by a systems integrator, a professional who researches the specific Quality Assurance (QA) needs of a production line and designs a tailored solution. This process is expensive and time-consuming, but the advent of Autonomous Machine Vision is revolutionizing the scene, making huge investments and long downtime a thing of the past. Here Yonatan Hyatt, CTO of Autonomous Machine Vision expert Inspekto, introduces the technology that makes it possible.

In the cinematic classic Modern Times, Charlie Chaplin interprets Charlot, a distressed factory worker whose only task is tightening bolts at an ever-increasing pace on an assembly line. Driven insane by this tedious and alienating job, he is eventually sent to a hospital to recover from a serious nervous breakdown.

Machine vision solutions were initially developed to liberate QA managers from the most Chaplin-like aspects of their jobs, monotonous and repetitive tasks that did not actively add value to the production line. Unfortunately, these traditional machine vision solutions come with many disadvantages: they have to be designed and installed by an external integrator, are expensive, and take a long time to create. Luckily, Autonomous Machine Vision (AMV) offers a revolutionary approach to QA, allowing manufacturers to have access to less expensive and user-friendly technology that does not require the intervention of any external expert.

The new alternative

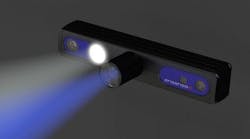

The technology that makes it possible is Plug & Inspect™, which has been developed by Inspekto, a German industrial company with Israeli DNA. It combines computer vision, deep learning and real-time software optimization technologies for a ground-breaking QA experience.

Its operating principle is simple: given a sample of good products—20 to 30, depending on their complexity—the system will learn the characteristics of a perfect item and signal any abnormality. The system takes into consideration different positioning of the item, light changes, and other environmental variables and is able to discern between them and actual defects. Furthermore, the system keeps learning and improving itself: if it flags a product as defective but an operator deems it as good, the same variation will not be considered again in the future.

Unlike traditional machine vision solutions, Plug & Inspect powered systems don’t need to learn how to recognize a faulty part. This is usually a time-consuming process that requires a certain number of items with various abnormalities, which the manufacturer may not have. On the contrary, Plug & Inspect learns based on good products.

Simpler, inexpensive, faster

Plug & Inspect can be installed in 30 to 45 minutes, more than 1,000 times faster than traditional machine vision solutions, whose design and installation usually takes from six weeks to a year. Moreover, any employer on the plant can easily set up and run the system independently, without the help of an external expert.

The technology is self-handling and self-adapting, meaning that the manager can decide to move it to other areas of the production line at any time, and thanks to its deep learning capabilities the system will adjust to suit the QA requirements of that particular junction. To top it off, the production line can keep running during set up, installation and change-over, eliminating the problem of downtime completely.

In Modern Times, Charlot prefers jail to his repetitive tasks at the factory, but thanks to this new technology, the tedious aspects of visual-manual QA are indeed a thing of the past. Plug & Inspect™ combines groundbreaking technology with the most user-friendly interface, to make QA managers love their jobs.