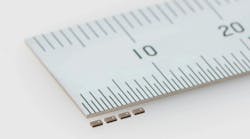

With a current rating of 2A per contact, the members of the Vivern family come in a 10-contact 1.45 mm pitch format and have an insulation resistance of over 1G?. They can be supplied in both cable-to-cable and cable-to-board configurations.

The lightweight but rugged construction of these compact (10.6 mm external diameter), polarized components means that they are well suited to implementation in high performance automotive applications (such as motor racing), as well as various other potentially high impact applications where there are also weight and space constraints to consider (including robotics and avionics). The breakaway collar incorporated into the bayonet locking mechanism can be sacrificed to protect against wired connector damage caused by adverse loads and external impacts. The contacts are made from a copper alloy with gold plate finish to augment their durability.

The Vivern connectors have been designed for use with 24 and 26AWG network cabling and each have an IP67 compliant sealed housing to combat liquid ingress. Thanks to the easily identifiable 3 color coded keyway options available, accidental incorrect mating of adjacent cables in densely packed electronic systems can be avoided. An operational temperature range of -65 to +150°C is supported, along with the endurance to enable completion of at least 1000 mating cycles. The PCB connector version features stainless steel board mount fixings to ensure that board retention is maintained, even when subjected to heavy vibration (exhibiting the resilience needed to withstand 20G for a period of over 6 hours).

Because of their combination compactness and strong current carrying capabilities, these units will be of value in relation to a wide array of different tasks where sensor/data acquisition hardware is involved. They are intended for use in telemetry systems, vehicle controls, pit lane equipment and automotive energy recovery system management, as well as unmanned aerial vehicles (UAVs), radar equipment, robot joint linkages, etc.