Custom Engineered Robot Transfer Unit

In order to address the needs of robot integrators, LazerArc has begun manufacturing the 7th Axis Slide, or Robot Transfer Unit customized to fit your application. Due to the low cost and high flexibility of Robotic Arms, they continue to be a popular choice in manufacturing. Robots are ideal for repetitive assembly operations, such as drilling, fastening, composite layup, welding, trimming, routing, painting and coating. Generally, they are mounted in a fixed location consequently limiting their reach. An additional axis is often required to make the robot more versatile.

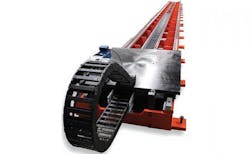

LazerArc can provide a heavy duty design to address this issue. It is equipped with high-precision helical rack and pinions that can handle the high dynamic loads and required accuracy. To extend the reach of the robotic arm, it is placed on a support carriage on a seventh axis slide and rack and pinions were chosen to drive the axis. By using rack and pinions in their modular base design, unlimited travel lengths could be achieved by mounting them end-to-end. Another advantage to 7th axis robotic slides is that more than one robotic arm can be placed on the same slide for additional productivity and flexibility.

LazerArc's line of Robot Transfer Units are manufactured in floor mounted, elevated or inverted configuration. With high precision guard rails, rack and pinnion systems, and closed loop motor control systems help you manufacture the best product possible. The Robot Transfer systems are capable of fitting into your automated robotic systems, whether it is a material handling job, paint, and assembling or welding application. All of the units can be adapted to your specific servomotor or robot brand.

LazerArc's RTU - 7th Axis system can be engineered to any length that the customer requires. Our design incorporates machined keyed ends allows for sections to be added or removed easily, when repurposing.

- Structural Steel Columns