Ultrasonic Thickness Measurement Sensors And Instrumentation

Santa Fe Springs, CA, – April 26, 2006 - The Ultracorr system combines the speed of intrusive monitoring sensors with the non-consumable nature of inspection devices. It represents a breakthrough for internal corrosion monitoring at locations that are difficult to access. Once installed, Ultracorr provides years of continuous service without the need for replacement.

The UltraCorr® System offers the following features:

• Non-intrusive Sensor

The sensor is simply attached to the exterior of the pipe/vessel surface, using a proprietary transfer adhesive, assisted by the magnetic shell of the sensor. While requiring a clean metal surface for attachment, no special surface preparation is needed.

• High Resolution

The resolution of the technique is more than an order of magnitude greater than conventional ultrasonic sensors. Estimation of corrosion rates are made in a matter of weeks, rather than years. The UltraCorr sensor is a true monitoring device, for permanent installation, providing frequent updates on corrosion rates in the user’s system.

• Non-Consumable

Unlike electrical resistance probes, the UltraCorr sensor does not require replacement, and will provide many years of uninterrupted service, without the need for routine maintenance. It is ideally suited for inaccessible locations, such as buried pipelines.

• User Friendly Measurement

Sensors are electronically tagged, to avoid confusion, when periodic measurements are made, and stored in the hand held, portable data logging instrument.

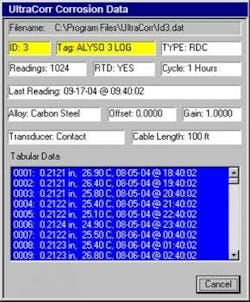

• Proprietary Analysis Software

Readings stored on the portable data logging unit can be uploaded to a PC, where proprietary software is used to organize, store, and graphically display data. Simple plots of thickness, versus time, are augmented with a cursor driven corrosion rate calculator permitting detailed event analysis.

Ultracorr will help solve the problem of monitoring in locations where sensor access is difficult, and will particularly suit buried pipeline operators faced with the problem of ICDA activities. After the initial dig to expose and ultrasonically examine HRHC (high risk, high consequence) locations, UltraCorr sensors can be installed on the line, and the excavation backfilled. They can subsequently be accessed for measurement via a test post, located at ground level, above the line. Readings can then be taken every 3-6 months to verify the corrosion behavior thereby minimizing or eliminating the need for costly future excavations.

Rohrback Cosasco Systems, Inc. (RCS) has been the world leader in corrosion monitoring since 1950. Through Rohrback instruments and COSASCO® access systems, RCS offers the largest selection of corrosion monitoring equipment for a variety of industries, including oil and gas, petrochemical, water treatment, chemical, pulp and paper, and pharmaceutical.• Thickness Measurement - Range: 0.1 - 2.0” (2.5 – 50mm) up to 100’ Cable o 2 – 2.0” (5-50mm) up to 200’ Cable o 4 – 1.25 (10 – 32mm) up to 300’ Cable • Instrument Operating Temperature - 32ºF - 122ºF (0ºC - 50ºC) • Data Storage - Memory Storage: Nonvolatile • Interface - USB (cables included), RS232 (optional) • Battery Requirements - 6 AA Alkaline • Size Approx. 4” x 8” x 2” (10cm x 20cm x 5 cm) • Weight - 1.5 lbs (0.068 kg) • Transducer Range: -10ºC to +85ºC